SUCCESS STORY | MOUNTED BALL BEARINGS

Screening Out Excess Expenses

Recycling industry

Synopsis

- Application: Polishing screen

- Problem: Failing eccentric collar mounted ball bearings

- Solution: Set screw mounted ball bearings

The problem

A single-stream materials recovery facility (MRF) in central Florida processes a collection of recyclable materials, from plastic to paper to metal, for various repurposing.

Early in the recycling process, material passes through a series of polishing screens set at a steep angle to quickly separate smaller items from larger plastics, corrugated paper, and metal containers, while letting debris fall through the screen’s surface. Each screen contains multiple shafts supported by four-bolt flange mounted bearings on either end to keep material flowing.

The high-vibration polishing screen application created significant solid, small-particle contamination that wreaked havoc on the existing competitive eccentric collar bearings. The existing 66 bearings were completely sealed in an attempt to withstand the high-contamination environment and therefore didn’t feature a grease zerk. Without the ability to be relubricated, the bearings frequently failed from overheating due to the increased radial load and temperature from magnetic tapes wound around a shaft–often destroying the shaft assembly in the process and causing significant unplanned downtime that cost $3,000 per occurance.

The success

After recurring competitive bearing failures, plant management replaced them with Dodge® set screw mounted ball bearings that provided substantially longer life—eliminating costly unplanned downtime, resulting in an

average annual savings of

Proven performance in the most extreme environments

Enhanced reliability for maximum uptime

Replacing failed competitive bearing and the supporting screen shaft was costly and laborious, requiring two technicians up to 6 hours to complete.

The test

Without the ability to be lubricated, the existing bearings were continuously failing within 2 years from overheating during operation. Plant management looked to Dodge for a more reliable solution for their polishing screens—beginning to replace existing competitive bearings as they failed with the Dodge set screw bearings.

The results

Exhibiting superior reliability without any failures for over 3.5 years when last verified, the easily installed Dodge set screw bearings substantially increased operation uptime by eliminating maintenance required to replace failing existing competitive bearings and damaged shaft assemblies.

Dodge set screw mounted ball bearings replaced the existing eccentric collar bearings on all polishing screens and provided notably better reliability.

The why

With premium features and world-class manufacturing quality, our set screw mounted ball bearings are the most reliable on the market. Their patented, mechanically-retained DualGuard sealing system protects against contamination while allowing grease to purge—delivering superior service life in dirty environments.

Utilizing a 65-degree set screw angle for the optimum balance between radial and axial holding power, their attachment method design provides superior locking force. When maximizing uptime is a priority for your operations, our set screw mounted ball bearings are proven to outlast the competition to be the problem-solving solution you need.

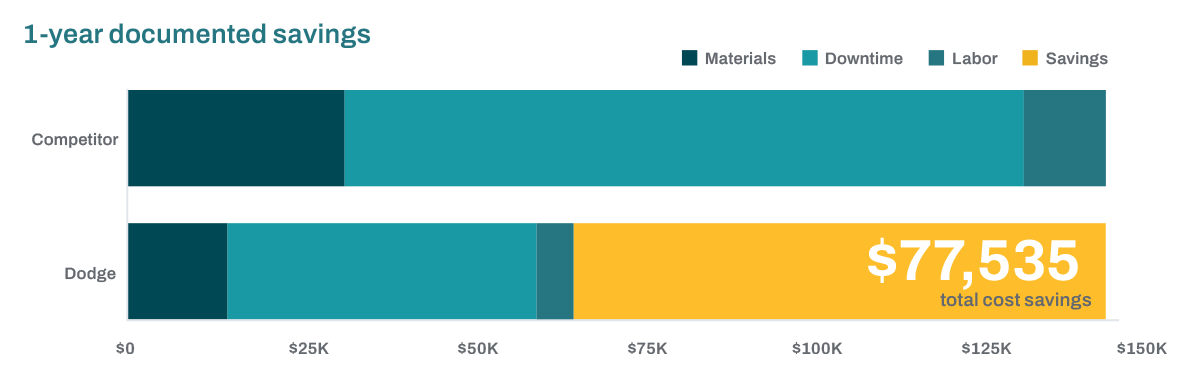

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.