SUCCESS STORY | MOUNTED TAPERED ROLLER BEARINGS

Elevating Efficiency and Cost Savings

Aggregate industry

Synopsis

- Application: Frac sand bucket elevator

- Problem: Premature bearing failure from contamination

- Solution: TAF mounted tapered roller bearing

The problem

A large frac sand plant in San Antonio, Texas operates around the clock, loading an average of 15,000 tons per day and producing over 3 million tons per year. Frac sand, a high-quality quartz sand, is critical to hydraulic fracturing for the production of natural gas and oil.

Uniform in shape and highly resistant to crushing, frac sand is produced from high-purity silica sand deposits—requiring a specialized process with strict specifications. After extraction, raw silica sand undergoes wet processing to remove impurities. The sand is then sorted by size, crushed, dried, screened for classification, and tested before being packaged for distribution. Critical to this process, bucket elevators are used throughout the plant to move material vertically—regularly exposing mounted bearings to the abrasive, fine silica material.

Competitive split bearings were used at the seven inch diameter head shafts, which required complicated on-site assembly and lubrication—making contamination upon installation inevitable. The bearings failed every 4 months, leading to costly unplanned downtime and lost production.

The success

Dodge® TAF mounted tapered roller bearings exceeded expectations by eliminating the opportunity for contamination during installation and outlasting the competition with over eight times the life, resulting in an

average annual savings of

The superior solution for tough applications

Shaft-ready features out of the box to ensure reliable performance

The five bucket elevators across the plant are difficult to access, making bearing replacements a laborious and costly task.

The test

After multiple competitive split bearing failures due to contamination during installation, the plant contracted Dodge for a reliable, easy-to-install solution. Two TAF mounted tapered roller bearings with an XTS triple-lip seal and an additional E-Tect seal were installed on one bucket elevator.

The results

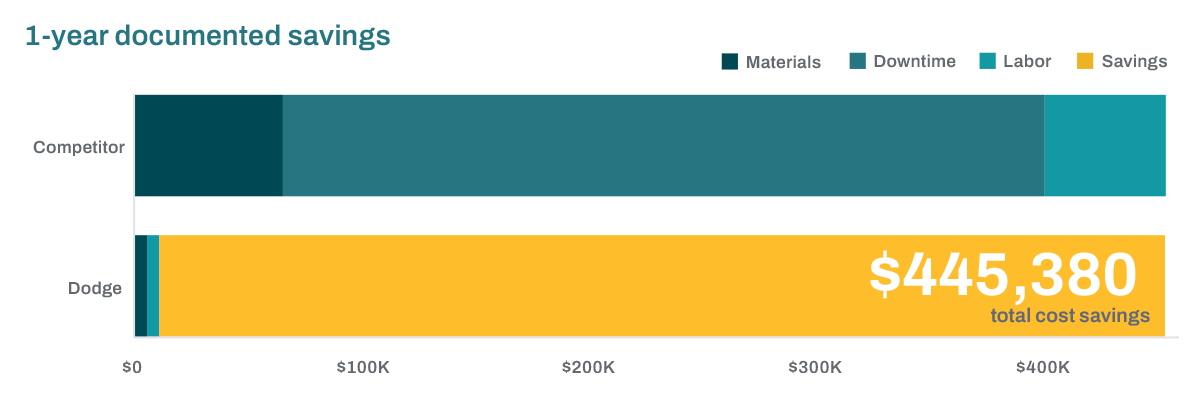

Arriving on-site fully assembled and prelubricated, TAF immediately proved superior to the previous solution. The streamlined installation eliminated exposure to the silica sand while minimizing labor and time, resulting in $445,380 of total cost savings. With one replacement in 33 months, the plant has since converted all five bucket elevators to TAF bearings.

With an easy installation, the preassembled and prelubricated TAF bearing proved to be an efficient, reliable solution for the challenging application.

The why

TAF bearings are factory-assembled and prelubricated, featuring a completely sealed S1 inner unit designed to mitigate potential contamination during installation. Its mechanically-retained XTS triple-lip sealing system with the additional E-Tect seal kit optimizes grease retention and allows efficient purging of old grease while preventing seal blowout, making it ideal for harsh environments with heavy contamination.

Sensor-ready and dimensionally interchangeable with SAF mounted bearings, TAF offers industry-leading capacity ratings—engineered to be the superior tapered solution for performance where you need it most.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.