SUCCESS STORY | GEARING

Not Taking Savings for Granite

Aggregate industry

Synopsis

- Application: Granite quarry belt conveyor

- Problem: Excessive downtime from reducer maintenance

- Solution: Motorized Torque-Arm (MTA) gear reducer

The problem

An aggregate mining operation, one of the largest quarries in the southeastern United States, produces granite products that serve major infrastructure and construction projects. The facility processes seven different types of aggregate material, with the primary focus being producing granite stone.

Mission-critical to the facility, belt conveyors move granite material to different stages of processing—from crushing to screening, storage, and loading—and rely on gear reducers to control the application’s speed for safe, smooth operation.

Requiring frequent V-belt tension adjustments and replacement of a complete unit on average every 3 months, the existing competitive belt-driven reducers on belt conveyors throughout the facility created significant unplanned downtime due to a shortage of adequately skilled maintenance staff. With downtime costing up to $18,000 per hour, plant management sought a more maintenance-friendly, reliable solution to address their maintenance workforce constraints, improve system efficiency, and maximize operation uptime.

The success

Through implementing MTA, the quarry eliminated routine maintenance tasks and improved application reliability—reducing unplanned downtime and resulting in an

average annual savings of

Proven reliability and performance

The direct-drive solution for maximum uptime in the harshest environments

The existing competitive belt-driven reducers required frequent maintenance attention and were unreliable, leading to excessive unplanned downtime.

The test

To mitigate maintenance requirements and unplanned downtime at the quarry, plant management decided to replace the existing competitive belt-driven reducers with Dodge® MTA direct-drive reducers for their belt conveyor drive applications.

The results

By implementing MTA, the facility resolved key operational challenges of excessive maintenance demands and frequent unplanned downtime. Based on the significant improvements with the initial installation of four MTA units, plant management is working to install MTA on all 40 belt conveyor applications throughout the facility.

The implemented MTA reducers enhanced reliability and reduced maintenance requirements—resulting in better belt conveyor operations.

The why

MTA stands out as the superior direct-drive, shaft-mounted reducer, being engineered for exceptional performance, reliability, and safety in demanding industrial applications. Its Hydrogenated Nitrile Butadiene Rubber (HNBR) sealing system, featuring a metal shield and excluder lip, ensures reliable operation—even in highly contaminated environments.

Designed to AGMA standards for 5,000-hour unadjusted L10 bearing life, MTA provides longer average reducer life than DIN-rated reducers. Its severe-duty backstop is the only shaft-mount reducer backstop engineered specifically for operation with extreme pressure (EP) lubricant, reducing component wear and extending service life.

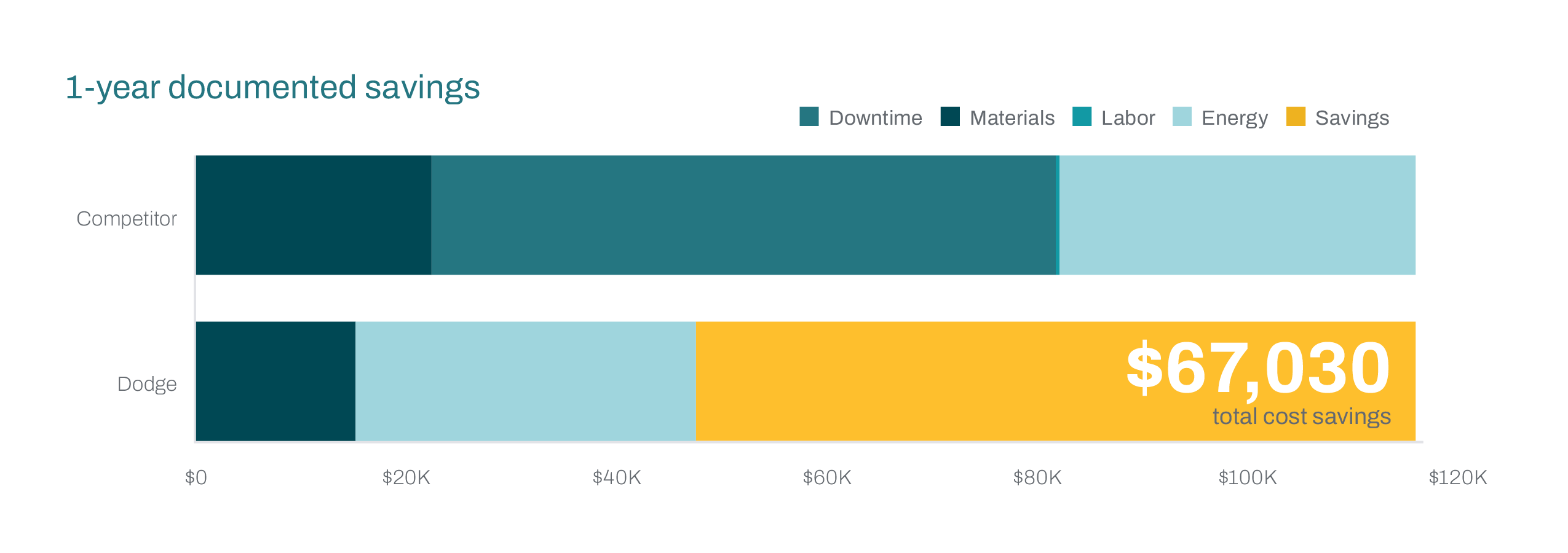

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.