OPTIFY™ Solutions Newsletter

Volume 1 | February 4, 2025

Leveraging condition monitoring data

Table of Contents

Industrial operations ask two key questions of condition monitoring solutions. The first—which critical assets are on the verge of failure? The second—what is the root cause of the pending failure? Using innovative sensor technology and robust data analytics, the OPTIFY portfolio of solutions answers these questions to help users avoid unplanned downtime.

When utilized across a facility on mounted bearings, gearing, and motors, Dodge sensor technology captures a wide range of key performance indicators (KPIs) from temperature and vibration to motor speed. This data is harnessed by the powerful OPTIFY platform, which uses a variety of methods to compile historical trends, compare like-assets, and set critical thresholds for each asset. When an asset begins displaying abnormal behavior, alerts and alarms are triggered—notifying the user where and when critical action is needed and empowering them with all the tools necessary for targeted maintenance before it’s too late.

Using vibration and temperature analytics provided in the platform, a user can pinpoint status changes to identify potential root causes. The platform is subscription-free and designed to be user friendly, making it easier than ever to harness the power of remote condition monitoring to enhance safety and reduce downtime at your facility.

OPTIFY applied: cost savings in action

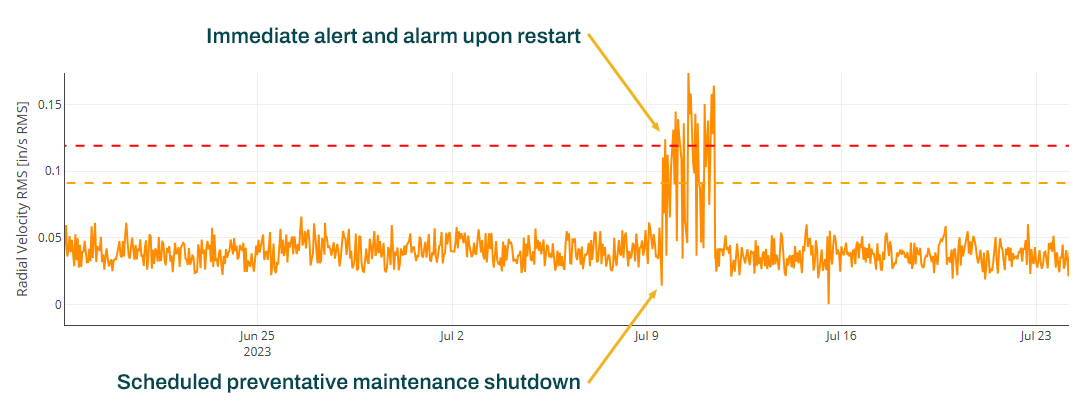

On July 9th, an OPTIFY platform user performed scheduled preventative maintenance (PM) on one of their belted blowers. The PM included the greasing of two bearings, belt adjustment, and a general inspection of the entire system. Upon completion, an alert was generated in the OPTIFY platform indicating abnormally high vibration on the maintained belt blower.

Upon investigation into the data analytics, an abnormal vibration frequency specific to belt harmonics was noticed. The maintenance team loosened the belts, immediately resolving the vibration issue and reducing the captured KPIs back to normal levels as seen in the chart below.

Without OPTIFY, the overtightened belts in the freshly maintained belt blower could have resulted in a bent shaft, bearing failure, and extensive system damage.

What’s new in the OPTIFY platform?

The latest improvements are designed to give you better insight to the status of your plant at a glance.

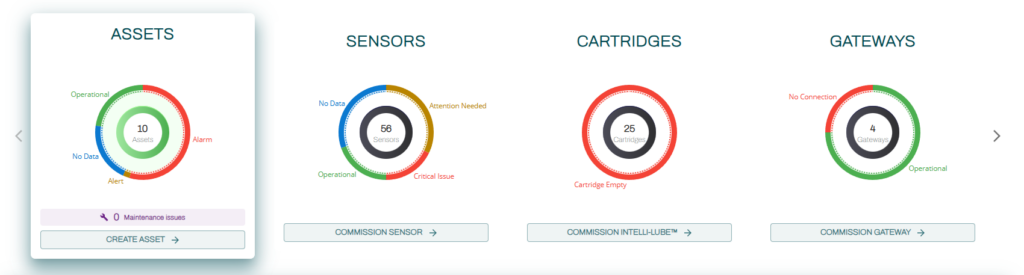

Dashboard refresh

Gain a better understanding of your plant health with a clear breakdown between asset health, sensor health, cartridge fill levels, and gateway status.

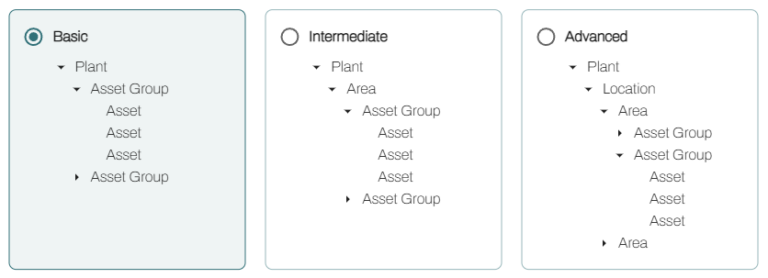

Plant setup

Multiple options are now available based on your plant size for an easier OPTIFY platform experience tailored to your needs.