SUCCESS STORY | MOUNTED SPHERICAL ROLLER BEARINGS

Keeping the Flour Mill Rolling

Grain industry

Synopsis

- Application: Flour mill roll stand

- Problem: Replacing rolls was destructive and time-consuming

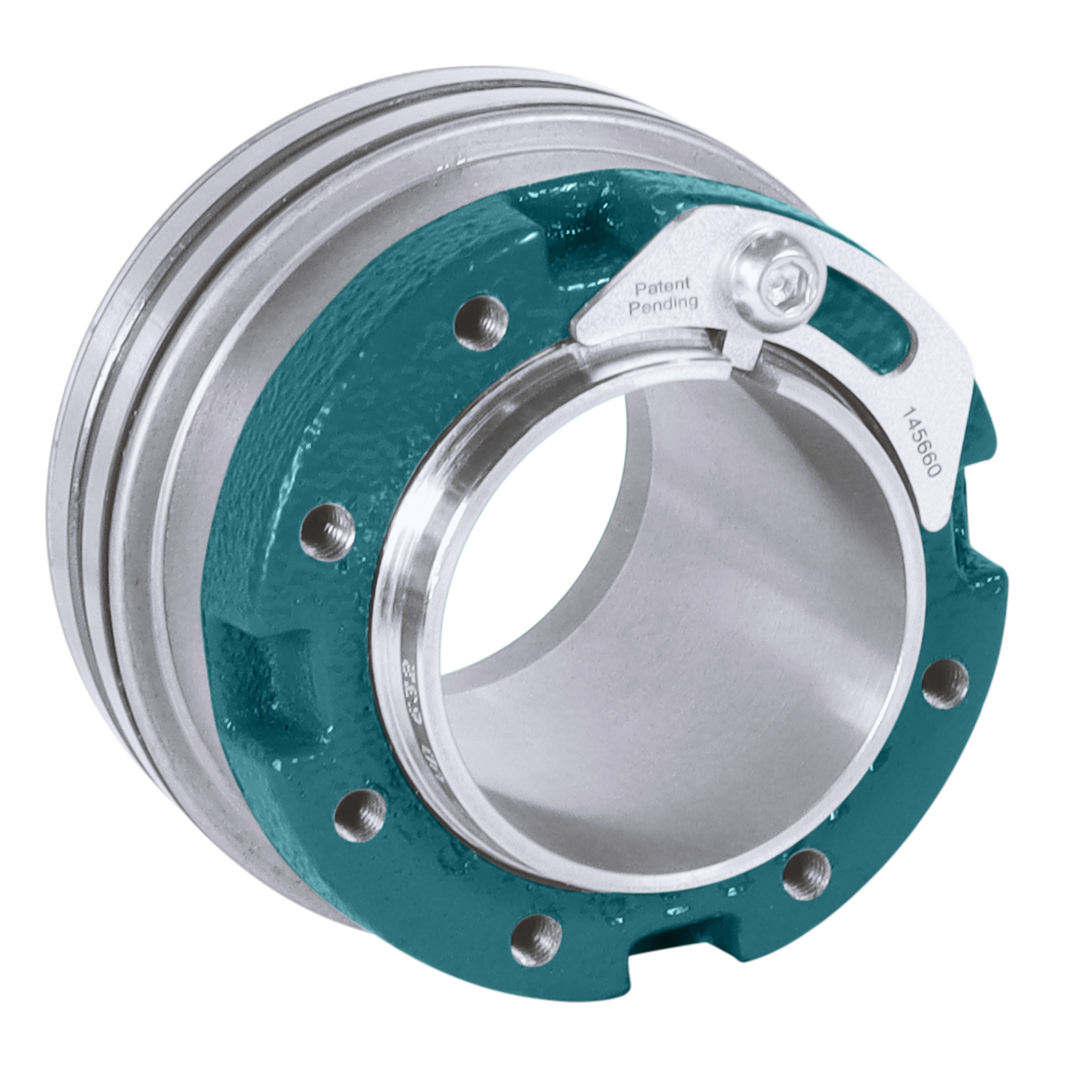

- Solution: Safety Mount® spherical roller bearings

The problem

A leading multinational agriculture products company based out of Minnesota produces flour by milling grain utilizing hundreds of roll stands from a single original equipment manufacturer (OEM) across all their flour mills.

Grain is processed through multiple roll stands to split the grain and grind the endosperm to produce the final flour product. The first phase breaks the grain to separate its outer bran, the germ, and the endosperm. The broken grain is run through additional roll stands until the desired consistency is achieved.

The roll stand has four rolls, a pair in the front and back, each supported by two bearings for a total of eight bearings. The rolls require frequent replacement and re-corrugating to keep grain crushing consistent. Each replacement was laborious and time-consuming, often requiring the roll to be cut off the stand—damaging the shaft and creating a dangerous environment in the dusty, potentially explosive conditions. The existing bearings were frequently failing due to flour particulate contamination.

The Success

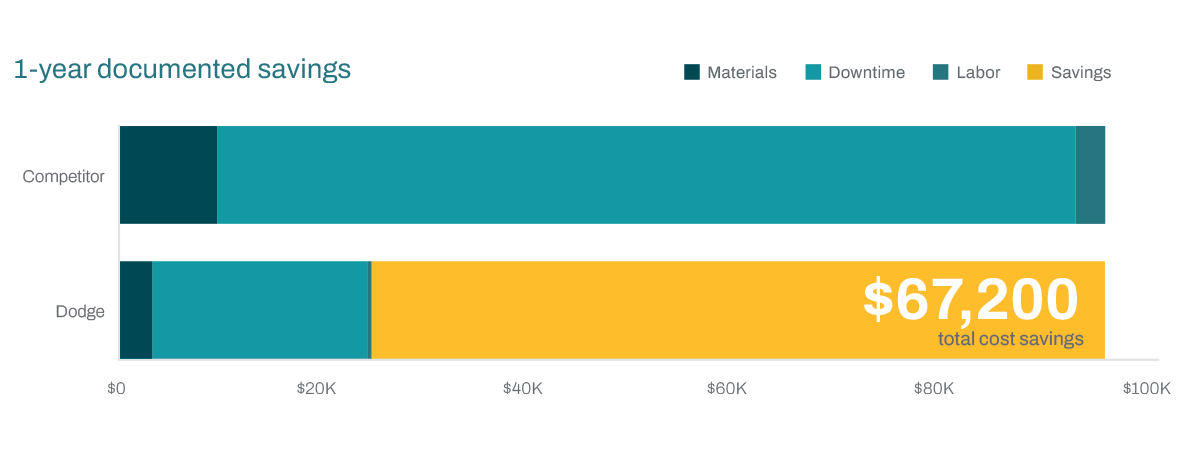

Dodge® Safety Mount bearings significantly reduced roll stand maintenance time, prevented shaft damage, and mitigated grease particulate contamination from flour for increased bearing life to maximize operation uptime—resulting in an

average annual savings of

Faster roll removal and installation with less stress

Reduce grease contamination, shaft damage, and downtime

Replacing the failed existing bearings required time-consuming maintenance and resulted in extensive downtime costs.

The test

Frequent roll replacements and bearing failures in the highly contaminated environment required excessive maintenance time. In order to facilitate faster and safer roll changes, plant management looked to the Dodge Safety Mount bearing to upgrade the existing roll stand designs.

The results

Plant management saw an immediate improvement with the Safety Mount bearing solution that allowed for quick and easy change-over of rolls without damaging the shaft—reducing maintenance and downtime from non-planned roll loss. Each removal and installation saved valuable time and money, and all roll stands throughout their flour mills have since been converted to the Dodge solution.

The Safety Mount bearing inserts installed on the roll stands minimized roll removal and installation time and improved bearing reliability to maximize operation uptime.

The why

The high-capacity Safety Mount bearing is preassembled to be shaft-ready out of the box and features a patented push-pull adapter mounting system for easy installation and removal without the use of feeler gauges or risk of damaging the shaft. Its tapered adapter sleeve concentrically grips the shaft to provide superior holding power without causing fretting corrosion or other damage to the shaft upon removal.

The premier Trident™ triple-lip rubbing seal with seal landing that maintains full contact, even when misaligned, is extremely effective at keeping contamination out of the bearing for long-lasting reliability. The Safety Mount bearing is engineered for superior performance in demanding applications to make it the ideal solution for your grain processing operations.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.