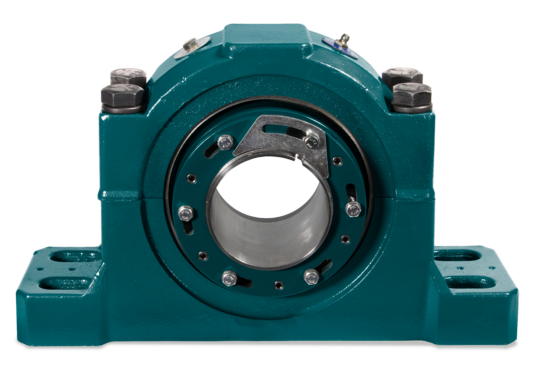

SUCCESS STORY | MOUNTED SPHERICAL ROLLER BEARINGS

Kiln the Game in Cost Savings

Forest products industry

Synopsis

- Application: Dry kiln fans

- Problem: Costly downtime due to lengthy maintenance

- Solution: Safety Mount® mounted spherical roller bearings

The problem

A top manufacturer of lumber products in the United States, owning approximately 1.8 million acres of timberland and operating multiple sawmills and plywood mills, was experiencing costly unplanned downtime when the SAF-style bearings on their dry kiln fans failed.

One of their lumber mills in Warren, Arkansas processes 220 million board feet per year of southern yellow pine. once received at the mill, logs are debarked, cut to length, cut down to boards, edged, trimmed, sorted, and stacked in preparation for the dry kiln processes. The dry kiln process, essential to wood production, dries the wood boards by circulating hot air through a chamber via large forced draft fans.

The fans used a competitor’s 4-15/16 inch SAF-style bearings, requiring two skilled maintenance workers, 6 hours of labor, and exact measurements using specialty tools for installation. In this harsh application, unplanned downtime due to bearing failure was occurring once per year and cost the manufacturer $40,800 per hour in production value.

The Success

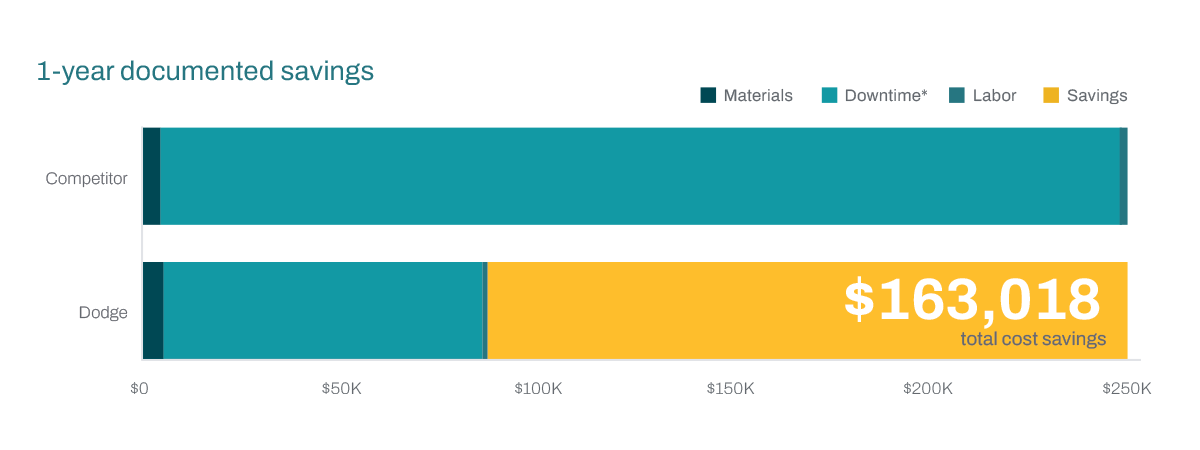

After testing Safety Mount’s easy installation and reliable operation, plan management decided to standardize their facility on Safety Mount, resulting in an

average annual savings of

4x faster installation than the competition

Minimize tools, risk, and time to maximize reliability, uptime, and savings

The circulation of hot air through the chamber is controlled by large forced-draft fans, crucial to production and utilizing 4-15/16 inch SAF-style bearings.

The test

Due to continued failures, lengthy installations, and critical uptime requirements in the mill, plant management tested two Safety Mount bearings on one of the fans in their drying kiln.

The results

As a drop-in replacement to the existing bearing, Safety Mount’s seamless installation of two hours versus the competitor’s six hours of downtime immediately impressed plant management. Without factoring in the increased reliability of the prelubricated Dodge® product, the valuable time savings for increased uptime and the impact on future productivity led them to standardize the mill on Safety Mount.

Safety Mount replaced a competitor's SAF-style bearing, immediately saving significant time and labor with its faster and safer installation.

The why

Shaft-ready out of the box, Safety Mount is a drop-in replacement for SAF-style bearings and features an innovative design with unparalleled advantages over the competition. Its patented dual lock nut eliminates the need for feeler gauges, subjective measurements, and manual calculations, resulting in immediate time savings and improving operational reliability. The patent-pending lock plate utilizes a single-bolt securement mechanism for 360-degree placement options with no hammering for a faster and safer installation. Built to revolutionize mounted spherical roller bearing installations, Safety Mount is the premier problem solver for critical applications.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.