SUCCESS STORY | GEARING

Bin It to Win It

Recycling industry

Synopsis

- Application: Baler incline conveyor

- Problem: Frequent integral gearmotor failure

- Solution: Quantis® right-angle helical-bevel gearmotor

The problem

A family-owned and -operated waste services company in southeast Wisconsin sorts and processes recyclable materials like paper and glass through a baler incline conveyor, being heavily reliant on mechanical power transmission solutions.

Once meticulously sorted and cleaned, the material is compacted and bound together using a baler, a powerful machine critical to the recycling process. Plant management had an opportunity to upgrade applications, including the drive packages for the baler incline conveyor.

The existing competitive integral gearmotor struggled with the baler incline conveyor’s heavy loads, leading to recurring motor failure. Additionally, maintenance struggled to remove the existing failed gearmotors from the shaft and had to use unsafe methods, including blowtorches and sledgehammers which damaged other equipment in the process, resulting in up to 3 days of downtime to get operations back up and running.

The success

Converting to Quantis eliminated the issue of frequent integral gearmotor failures that required full assembly replacement, making an immediate positive impact on operation uptime and resulting in an

average annual savings of

Proven reliability and performance

The modular gearmotor for lower total cost of ownership

The baler incline conveyor with Quantis gearmotors ensures material continuously flows to the next recycling phase.

The test

Plant management looked for an alternative gearing solution to the existing integral gearmotor that continuously failed. Building on their previous success with Dodge®, management decided to try Quantis equipped with twin-tapered bushings for the high-ratio drive packages at the baler incline conveyor application.

The results

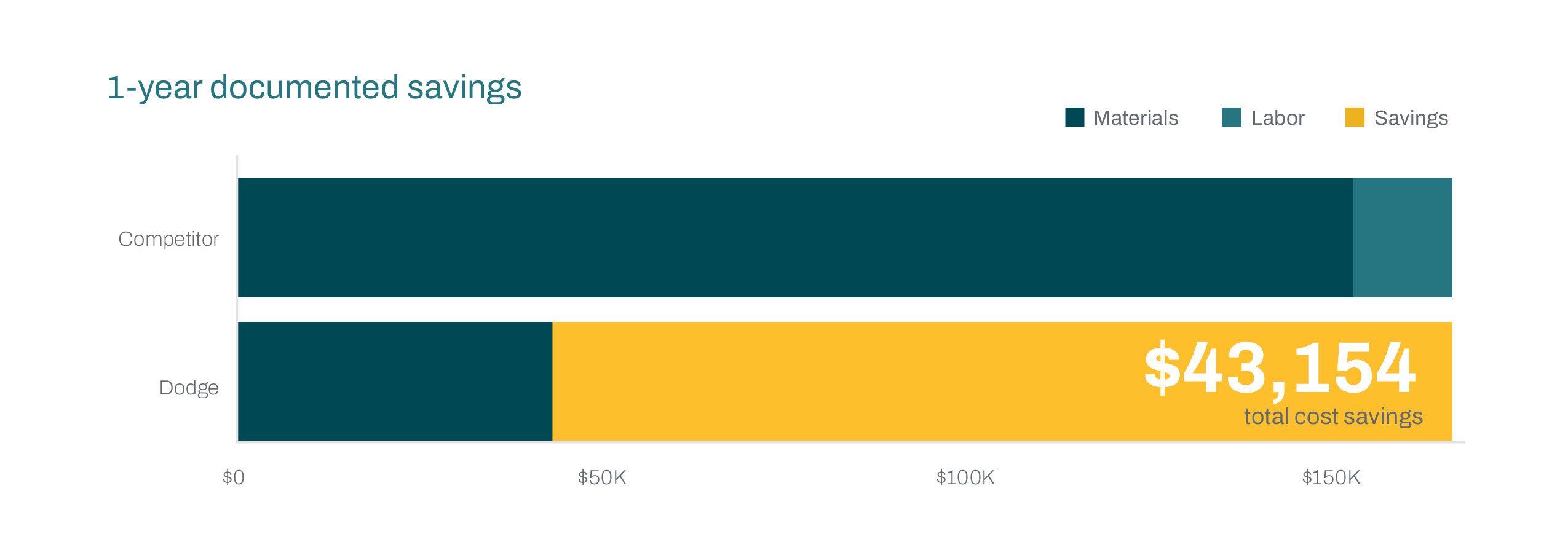

During its first year, Quantis consistently delivered exceptional results—leading to substantial cost savings. The plant avoided $36,000 in lost production expenses and reduced total downtime costs by over $14,000 annually.

Quantis replaced the competitive gearmotor, providing reliable performance for an immediate positive impact to uptime and long-term cost savings.

The why

For critical applications, Quantis gearmotors offer power and flexibility—featuring greater torque ratings than competitive reducers for extended service life and the ability to pair seamlessly with C-face motors to streamline maintenance.

Quantis is available with our patented twin-taper bushing system for shaft-mounted applications to provide easy installation and guaranteed removal in shaft-mounted applications, saving valuable time and money. Featuring case-hardened helical gearing and an industry-leading sealing system, Quantis is the go-to modular solution for reliability, consistent performance, and maximum uptime.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.