SUCCESS STORY | MOUNTED BALL BEARINGS

Breader than the Competition

Food processing industry

Synopsis

- Application: Breader machines

- Problem: Bearing failures every 2 months

- Solution: E-Z Kleen® mounted ball bearings

The problem

A global producer of protein products was experiencing ongoing issues with bearing failures on machinery in the breading process at one of their plants in Alabama.

Breader machines containing various rotating drums and screens apply a fine, powder-like breading mixture to chicken moving through the line. The breading mixture acts as a harsh abrasive to mounted bearings in the machines. The existing bearings continually failed every 2 months due to contamination from the breading mixture bypassing the sealing system.

In one instance of bearing failure, parts of the competitive bearing’s rubber seal broke off and mixed in with the food product—making their way through the metal detectors unnoticed and leading to $80,000 of scrapped chicken product. In total, this singular instance of bearing failure resulted in a $240,000 loss between unplanned downtime, labor, and wasted product.

The success

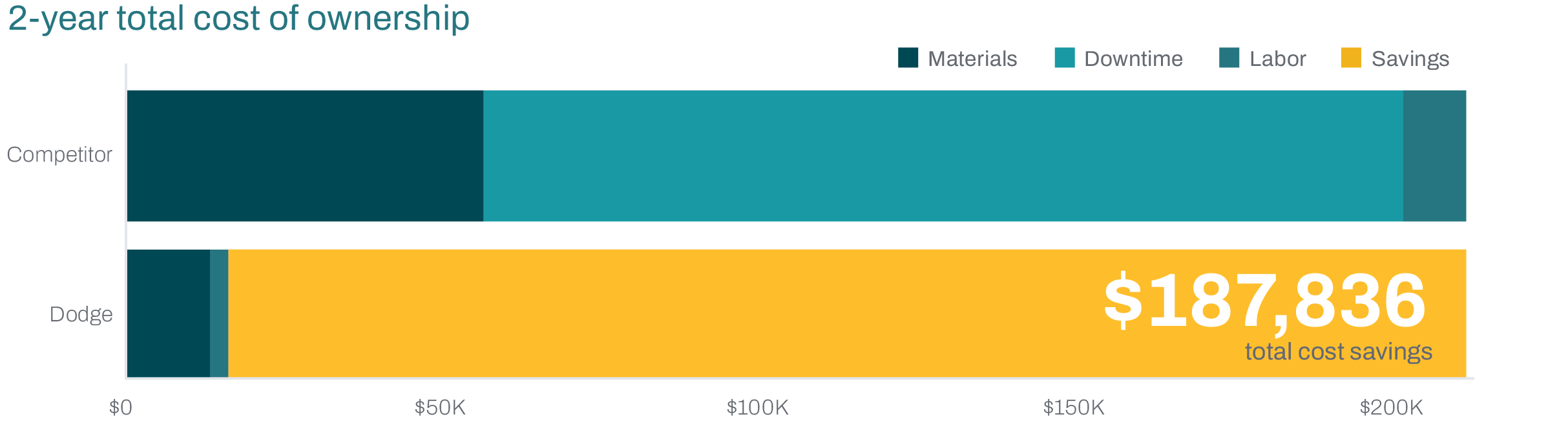

After a period of testing, plant management decided to replace every mounted ball bearing in their facility with E-Z Kleen mounted ball bearings, resulting in an

average annual savings of

Setting the diamond standard

No fuss. No downtime. No brainer.

The powdery breading mixture acts as a harsh abrasive, creating a demanding environment in which only the most reliable solutions survive.

The test

Due to the continual failures of the competitor’s bearings, plant management consulted with Dodge® field sales and engineering to find the best solution for their needs. With 48 bearings across three breader machines, they decided to run a trial on one machine with E-Z Kleen bearings.

The results

After installation and several months of smooth and worry-free operations, plant management standardized the entire facility on the modified E-Z Kleen bearing.

E-Z Kleen bearings replaced every bearing on the breading machines, becoming the standard throughout the facility.

The why

E-Z Kleen bearings are a proven choice for food processing environments. From corrosion-resistant components

to food-grade lubricant and robust sealing systems, E-Z Kleen bearings continously outlast the competition. Product strength, design, and technical support set the Dodge solution apart from the rest as the premier choice—earning plant management’s trust and saving the facility hundreds of thousands of dollars in unplanned downtime for years to come.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.