SUCCESS STORY | ELASTOMERIC COUPLINGS

Bursting the Competition’s Bubble

Wastewater industry

Synopsis

- Application: Paddle wheel aerator

- Problem: Costly downtime due to premature coupling failure

- Solution: Raptor elastomeric coupling

The problem

A sewage commission facility in an area of Wisconsin, renowned as a vibrant tourism hub, was experiencing recurring premature failure of competitive urethane couplings used to connect shaft-mounted reducers to paddle wheel aerator shafts. The facility services the community which hosts over 2.8 million visitors annually, playing a crucial role in managing wastewater amidst escalating seasonal flows.

The existing couplings used in the facility’s oxidation ditch, a critical part of biologically treating wastewater, with multiple aerators experienced frequent separation of the urethane bond from the element flanges.

The facility encountered further complications with costly maintenance from having to replace two failed mounted bearings on each aerator cause by the unreliable competitive coupling performance. These issues added to the facility’s workload and material expenses, highlighting the pressing need for effective solutions to enhance operational reliability and reduce unnecessary maintenance.

The success

After replacing the plant’s failing elements with the more reliable Raptor, the facility saw improved driven equipment life and a

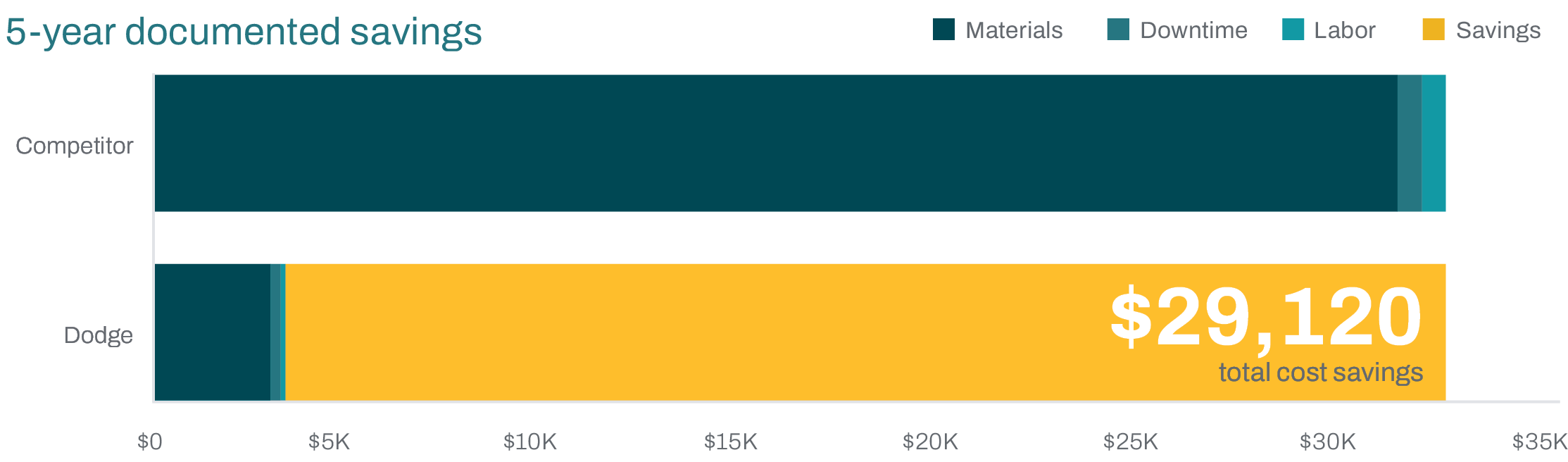

5-year total savings of

Engineered to outlast the competition

Reduce wasted resources with best-in-class reliability and performance

The competitive urethane couplings routinely experienced urethane bond degredation, failing to stand up to the harsh environment of the oxidation ditch.

The test

At 8,400 running hours per year, the plant was replacing competitive urethane couplings yearly on average for each aerator. Due to the coupling failures and costly mounted bearing replacements on the connected driven equipment, plant management looked to Dodge® for using Raptor as a reliable solution to their oxidation ditch aerator pitfalls.

The results

As a drop-in replacement for the competitive coupling, the Raptor element was easily installed on the existing coupling hubs with no modification. It seamlessly surpassed the 1-year life of the competitive coupling, leading management to convert all their aerators to using Raptor. Monitoring performance for years after, Raptor demonstrated improved reliability with at least five times longer life than the existing coupling for significant maintenance and cost savings.

Raptor with its natural rubber element design replaced the competitive urethane couplings, instantly improving application reliability.

The why

Interchangeable with competitive designs and proven to perform in the most demanding applications, Raptor is engineered to maximize your uptime. Unlike urethane-based couplings that experience bond degradation between the urethane element and metal clamp rings when exposed to water, Raptor’s natural rubber element resists hydrolysis for best-in-class reliability in damp environments.

Its element with patented WingLock design increases surface area to maximize fatigue resistance and provides lower bending stiffness than competitive urethane designs for reduced load in mounted bearings on connected equipment—significantly extending driven equipment life and lowering your total cost of ownership. Product durability and performance set Raptor apart as the elite coupling solution for operations that demand the best.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.