SUCCESS STORY | GEARING

Conveying Bark and Savings

Forest products industry

Synopsis

- Application: Debarker waste conveyor

- Problem: Integral gearmotor failures every 6 weeks

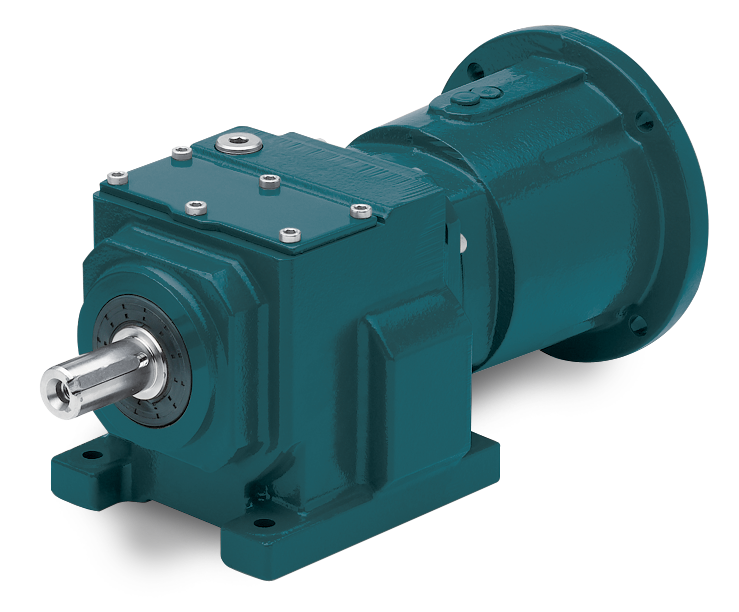

- Solution: Quantis® in-line helical gear reducer

The problem

Based out of Vancouver, British Columbia with locations in the Pacific-Northwestern United States, a leading wood products company uses mechanical power transmission solutions to optimize manufacturing while supporting forest sustainability.

With eight sawmills producing more than 1.1 billion board feet annually to meet the demands of a growing world, each operation must run smoothly to maximize output. Debarking, the process of removing bark from logs received at a mill, is an essential step at the beginning of lumber production—preparing wood that flows through the rest of the process. During debarking, the excess material travels down a waste conveyor to be saved and repurposed for alternative uses.

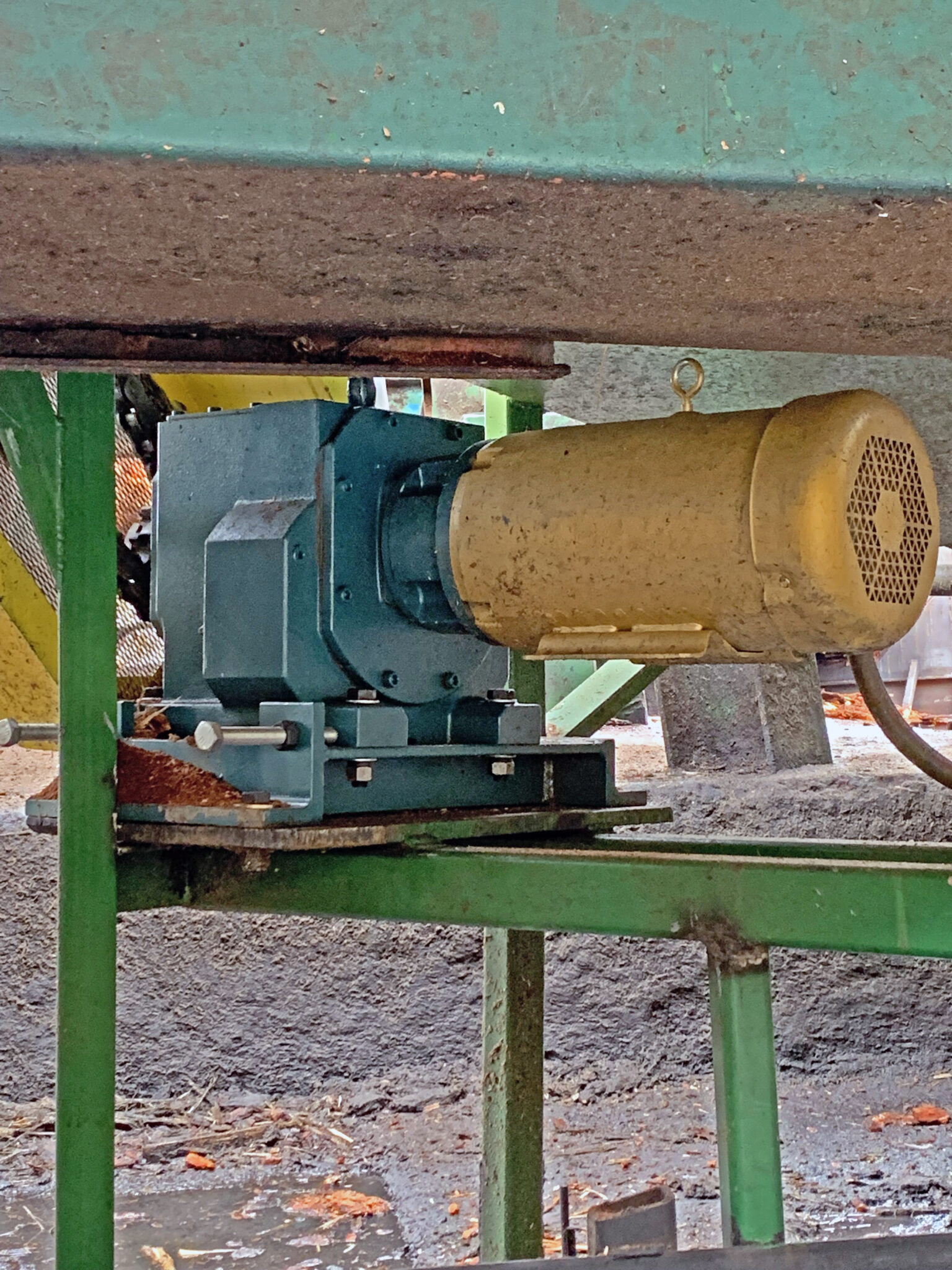

One of their sawmills in Washington was experiencing frequent unplanned downtime due to a competitive integral gearmotor on the debarker waste conveyor failing. The existing integral gearmotor failed every 6 weeks from motor issues caused by excess material build-up on top of the unit, taking two skilled millwrights 4 hours to replace the entire gearmotor assembly and costing $36,000 in annual lost production value.

The success

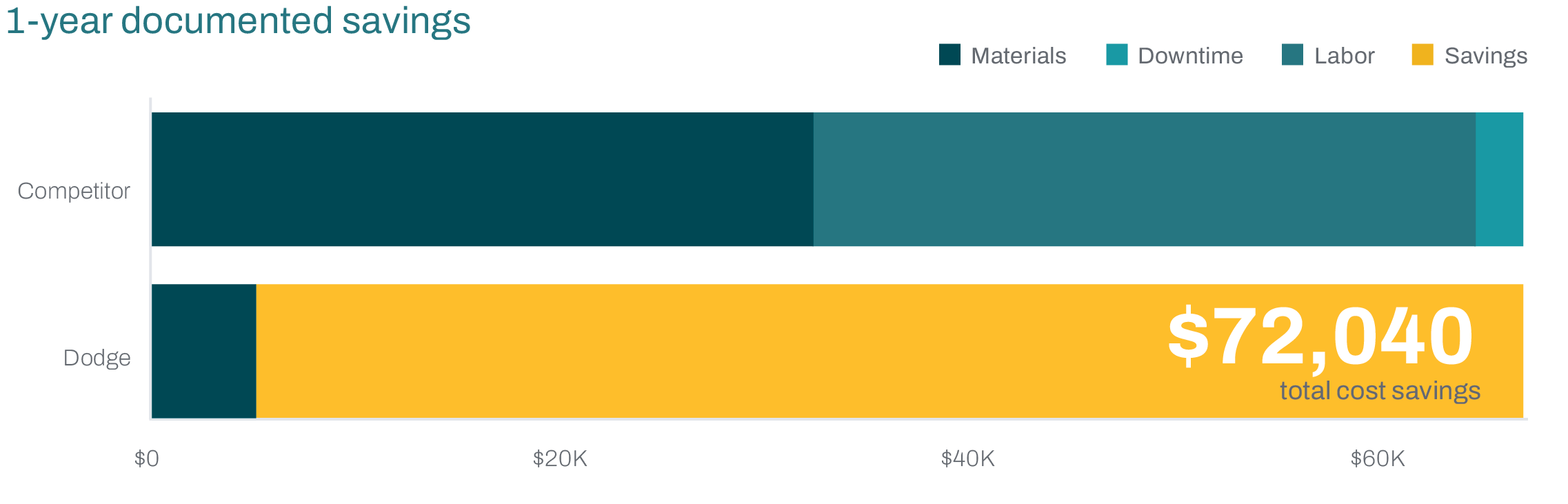

With the initial replacement, Quantis eliminated the operation’s bottleneck to immediately reduce maintenance requirements and impact productivity, resulting in an

average annual savings of

Proven reliability and performance

The modular reducer for lower total cost of ownership

Replacing the entire competitive gearmotor assembly was expensive and labor-intensive, requiring two skilled millwrights 4 hours to complete.

The test

Frequent failure of the competitive integral gearmotor from damage due to the motor continuously tripping, which required replacing the gearmotor assembly in its entirety each time, led management to try a Quantis in-line helical gear reducer on their debarker waste conveyor.

The results

Performing reliably without failure for over a year when last verified, Quantis substantially increased sawmill uptime by eliminating the operational bottleneck caused by the existing integral gearmotor. In addition to better reliability, the reducer streamlined maintenance through its ability to use C-face motors and replace a failed motor independently from the reducer—significantly reducing material and labor costs.

Quantis replaced the competitive gearmotor, providing easier maintenance with more reliable performance for an immediate cost savings.

The why

True to the Dodge® standard of best-in-class reliability, Quantis is engineered with a robust sealing system and case-hardened helical gearing to be a durable, efficient reducer. Quantis features greater torque options for extended service life and pairs seamlessly with C-face motors to simplify gearmotor maintenance—expanding application flexibility while outlasting the competition.

For shaft-mounted applications, the reducer is available with our patented twin-tapered bushing system for streamlined installation and guaranteed gearbox removal every single time. When saving money and maximizing uptime is a priority for your operations, Quantis is the go-to modular solution for your gearmotor needs.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.