SUCCESS STORY | MOUNTED SPHERICAL ROLLER BEARING

Drumming up Savings

Forest products industry

Synopsis

- Application: Rotary drum dryers

- Problem: Labor-intensive failed bearing replacements

- Solution: Hydraulic ISAF mounted spherical roller bearings

The problem

As one of the world’s largest pulp and paper companies, a North American manufacturer runs 21 manufacturing plants across the country—relying heavily on mechanical power transmission products to keep operations moving smoothly and efficiently.

Widely used in a variety of construction applications, oriented strand board (OSB) is a leading building material known for its cost-effectiveness and sustainability. OSB production starts with trees as raw material, moving them through a process of debarking, chipping, drying, filtering, blending, pressing, and trimming to produce finished panels. Critical to this process is the drying phase, in which wet wood chips are fed into rotary drum dryers and continually agitated as hot air is circulated throughout the drum.

At an OSB plant in the southeast, the eight-inch bore, SAF-style bearings on the rotary drum dryers were regularly failing. Each failure required a 2-day replacement using a crane to support the dryer, costing $26,700 in labor and materials. With a total of 24 bearings on dryers across the mill, four were being replaced per year—resulting in a total annual cost of $106,800.

The success

Hydraulic ISAF immediately impressed plant management with its faster and safer installation, leading them to standardize their facility with Hydraulic ISAF, resulting in an

average annual savings of

Safer. Faster. Easier.

Patented features for lower total cost of ownership

The removal and replacement of the competitive SAF-style bearing was labor-intensive, requiring two full days, multiple people, and specialty tools.

The test

Repeated failure and costly replacement of the competitive SAF-style bearings led plant management to try Hydraulic ISAF bearings on their rotary drum dryers.

The results

Interchangeable—both dimensionally and functionally—with the existing bearing, Hydraulic ISAF allowed for a seamless installation with significant time savings—cutting both labor and crane use in half to considerably reduce safety risk and associated equipment cost. Its ease of replacement and increased reliability for lower total cost of ownership made Hydraulic ISAF the easy choice for increased uptime in the mill’s operations.

Hydraulic ISAF replaced a competitive SAF-style bearing, providing a substantially faster and easier installation with immediate cost savings.

The why

Factory-assembled, lubricated, and sealed, Hydraulic ISAF is shaft-ready out of the box for streamlined installation with zero opportunity for contamination. Its innovative design offers numerous advantages over the competition. With an integrated hydraulically-assisted adapter mounting system, Hydraulic ISAF can be installed and removed quickly and easily from one side by a single person without the use of a torch or specialty tools. Its automatic, accurate internal clearance setting eliminates the need for feeler gauges and manual calculations, minimizing risk of inconsistent installations for increased reliability. When it comes to saving time and money, Hydraulic ISAF is the advantageous solution for demanding applications.

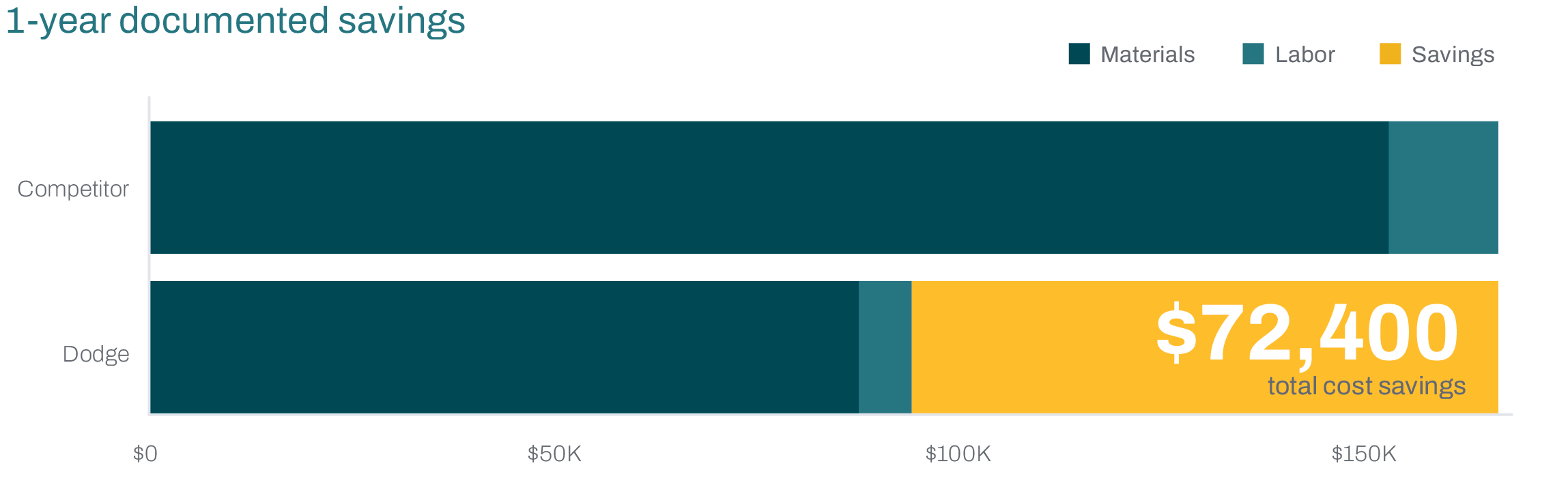

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.