SUCCESS STORY | IIOT TECHNOLOGIES

Eliminating Slurry Fury

Aggregate industry

Synopsis

- Application: Centrifugal slurry pumps

- Problem: Pump failures due to contamination

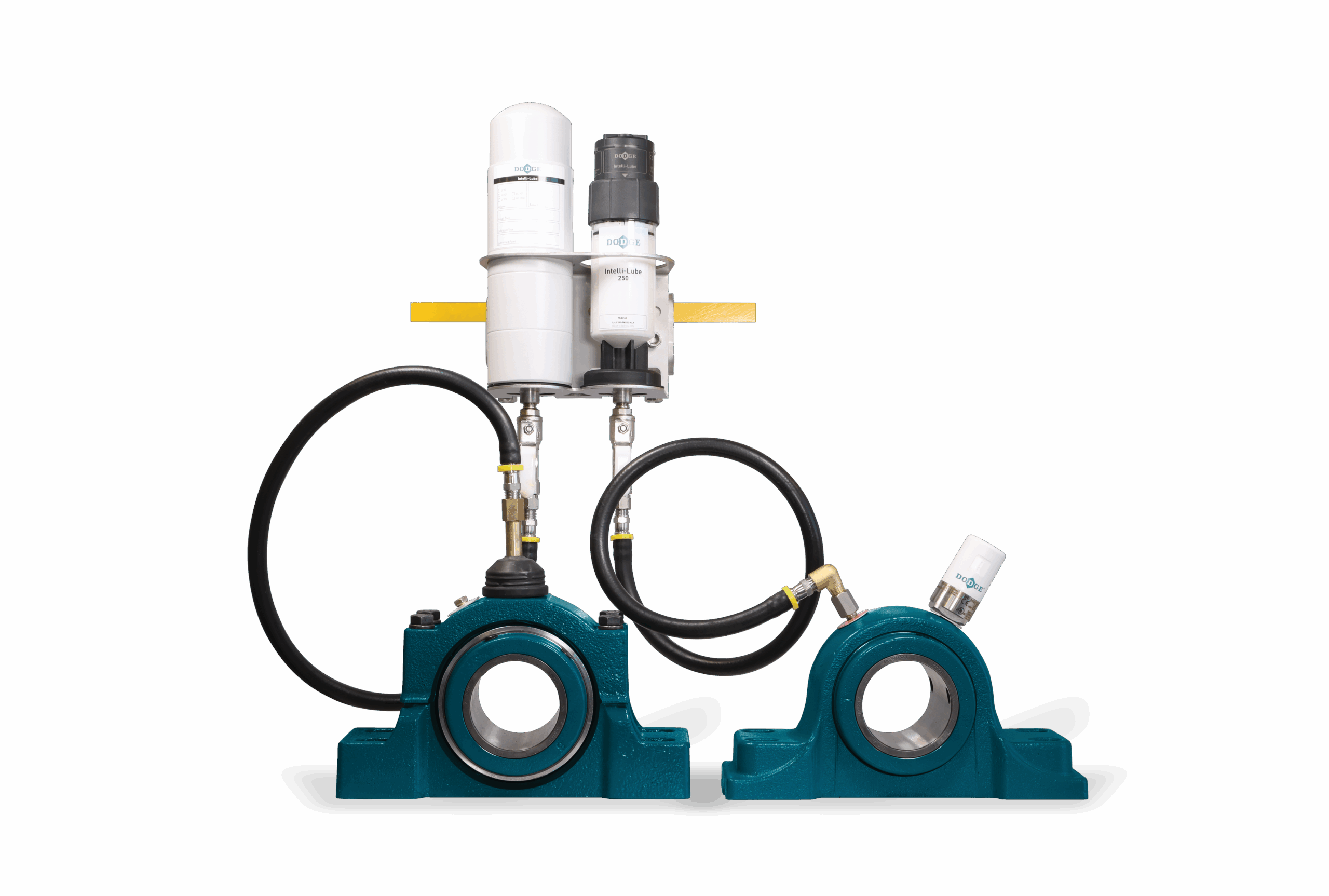

- Solution: OPTIFY™ Intelli-Lube® automatic lubricators

The problem

One of the largest frac sand producers in Texas manufactures over 3 million tons annually and is capable of loading 15,000 tons per day. Frac sand is a high-purity quartz material that’s used to create cracks in shale rock layers during hydraulic fracturing, commonly known as fracking.

To produce frac sand, material is blasted and run through a series of conveyors to be cleaned, dried, crushed and sorted. The sand must be uniform in shape and hardness to have the strength and filtration capabilities to effectively hold open the cracks.

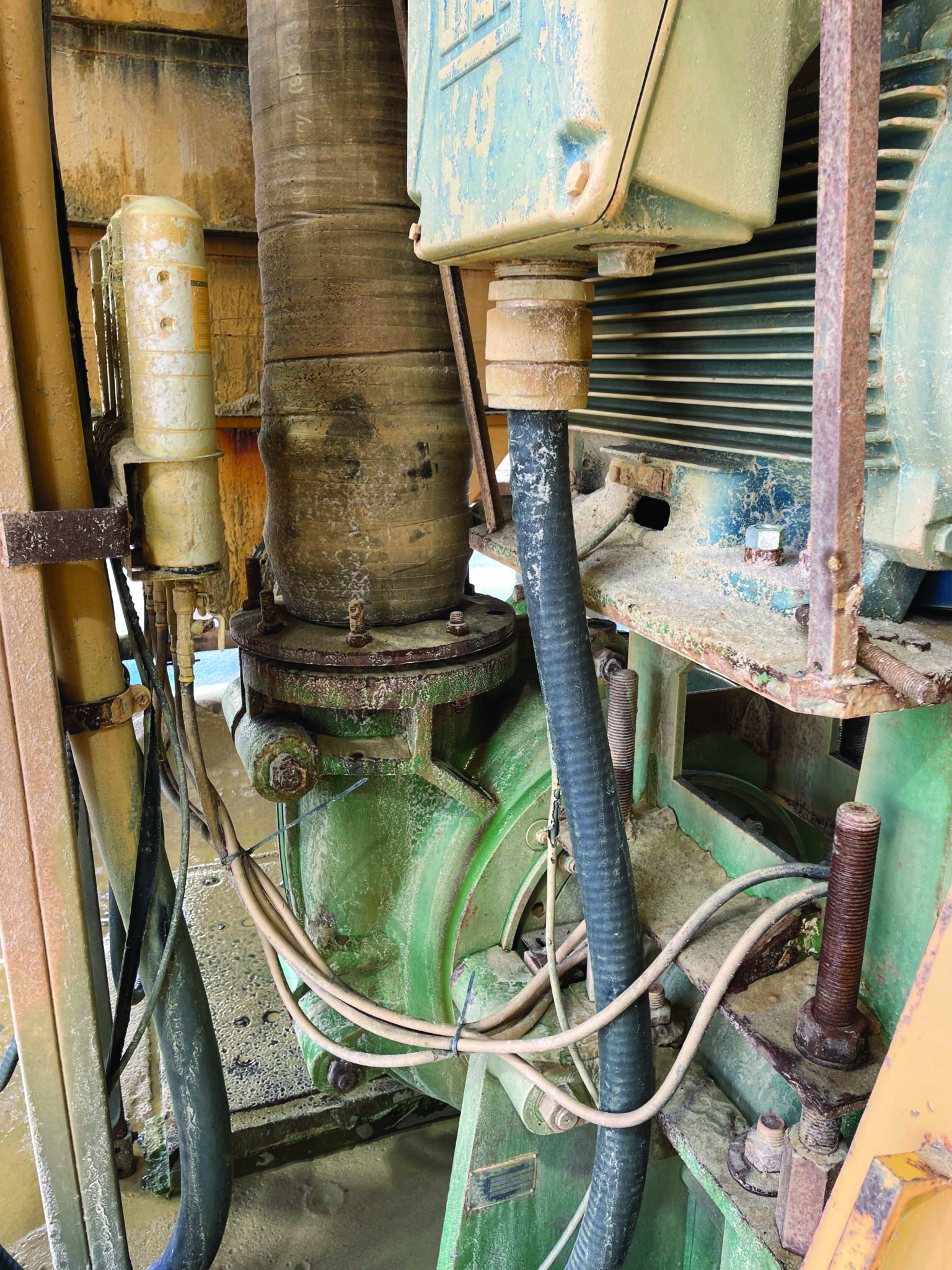

Centrifugal slurry pumps are used to help move product throughout the process. A full-time employee manually greased the pump bearings to purge contaminants but could not keep up with the demand to protect the bearings from high levels of water and corrosive-material ingress. The slurry pumps were failing every 2 weeks due to contamination, costing approximately $120,000 in materials, labor, and lost production due to unplanned downtime per failure.

The success

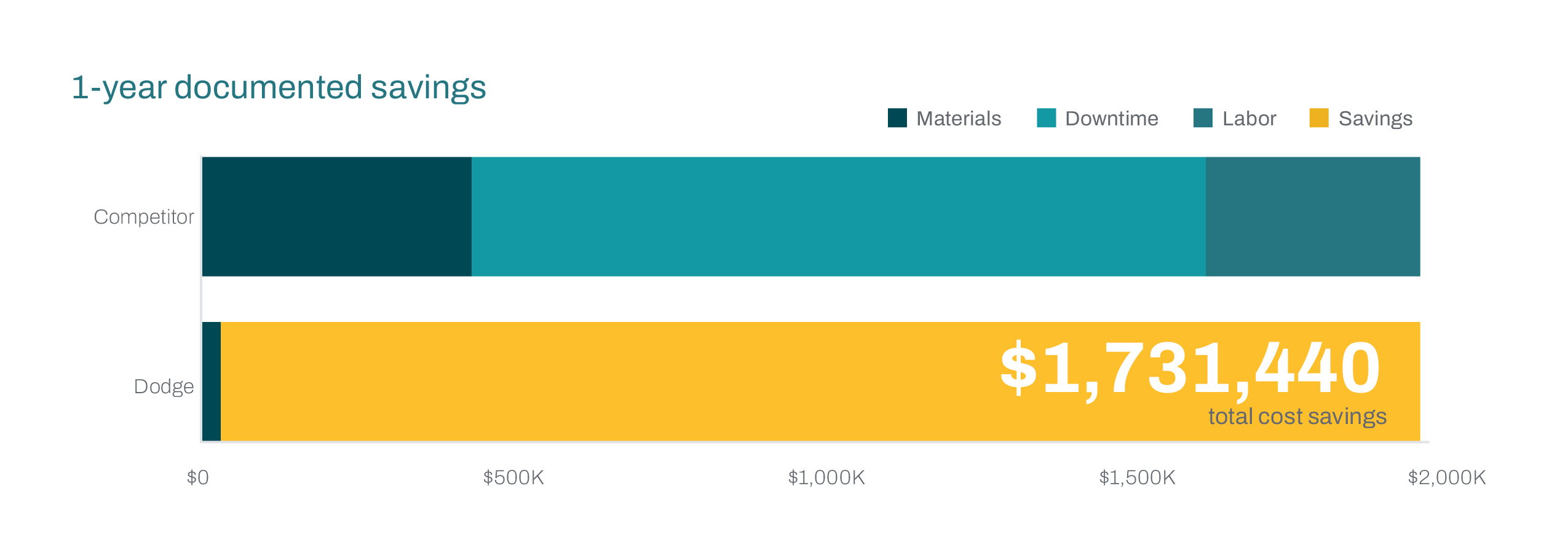

The frac sand producer’s implementation of OPTIFY Intelli-Lube automatic lubricators saved hundreds of hours of manual greasing labor, prevented pump failures, and mitigated costly downtime—resulting in an

average annual savings of

Technology to work smarter, not harder

Connected, hands-free lubricator provides the right amount of grease at the right time

Contamination ingress due to environmental conditions led to slurry pump failures every 2 weeks.

The test

Plant management considered expanding manual greasing efforts or implementing alternative lubrication systems but chose the Dodge® solution because it offered an automated remedy with the user-friendly OPTIFY condition-monitoring platform to view lubricator health and manage inventory at a cost-effective price point.

The results

The 34 OPTIFY Intelli-Lube units were easy to install on the 11 pumps, and the lubrication intervals were dialed in using the OPTIFY platform. Since the initial installation, there have been no pump failures for over a year and manual greasing efforts were eliminated, leading plant management to plan on installing OPTIFY Intelli-Lube units on all pump bearings and other critical bearings throughout the facility.

Since installing OPTIFY Intelli-Lube, the plant has seen an immediate positive impact to operations with no pump failures in over 1 year.

The why

OPTIFY Intelli-Lube is the premier automatic, single-point lubricator that replaces the manual bearing lubrication process for worry-free operations—streamlining maintenance, lowering costs, and improving on-site safety with the right grease, volume, and interval every single time.

OPTIFY Intelli-Lube connects to the OPTIFY platform, monitoring the lubricator to ensure critical bearings are properly lubricated and notifying you when replacement cartridges are needed. The platform allows you to remotely monitor the health of your equipment and take a predictive approach to maintenance—increasing reliability, saving time, reducing costs, and enhancing on-site safety for optimizing your operations. Slurry pump failures used to be a major pain point. Not anymore.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.