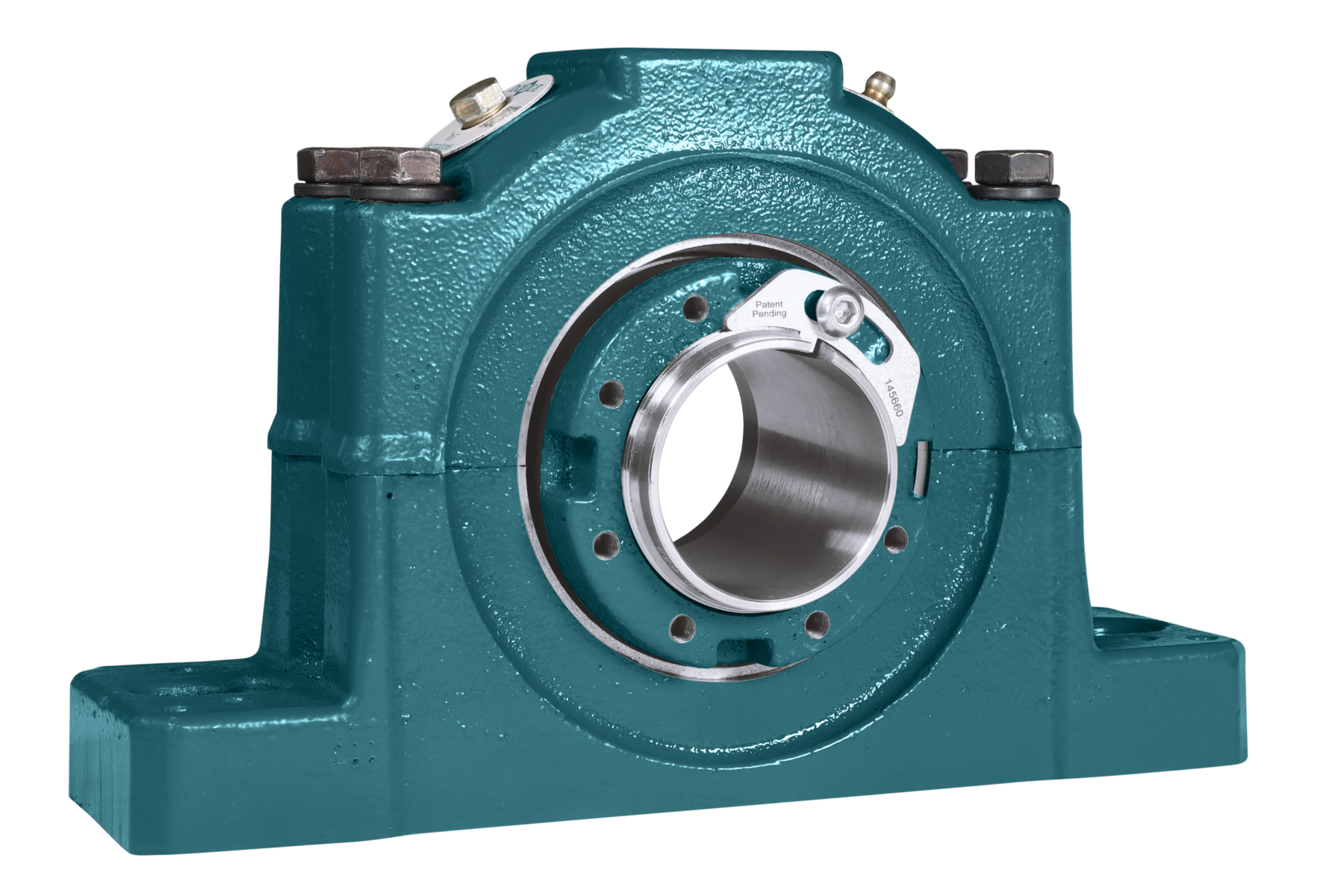

SUCCESS STORY | MOUNTED SPHERICAL ROLLER BEARINGS

Feeding Uptime and Savings

Grain industry

Synopsis

- Application: Air relief system blower fans

- Problem: Critical bearing failures causing costly shutdowns

- Solution: Safety Mount® ISAF mounted spherical roller bearings

The problem

In the $94 billion dog food market, an industry-leading grain processing plant in southwestern Missouri plays a crucial role by producing a significant portion of the global dry and wet dog food supply.

The dog food manufacturing process involves multiple stages, including raw material assembly, meat rendering, grinding, mixing, extruding, drying, cooling, and packaging. During the food and grain grinding phase, blower fans ensure the air relief system does not overheat and maintains a clean, moisture-controlled production environment. The fans play a vital role in mitigating equipment failure, preventing contamination, and reducing bacterial growth that can lead to product spoilage.

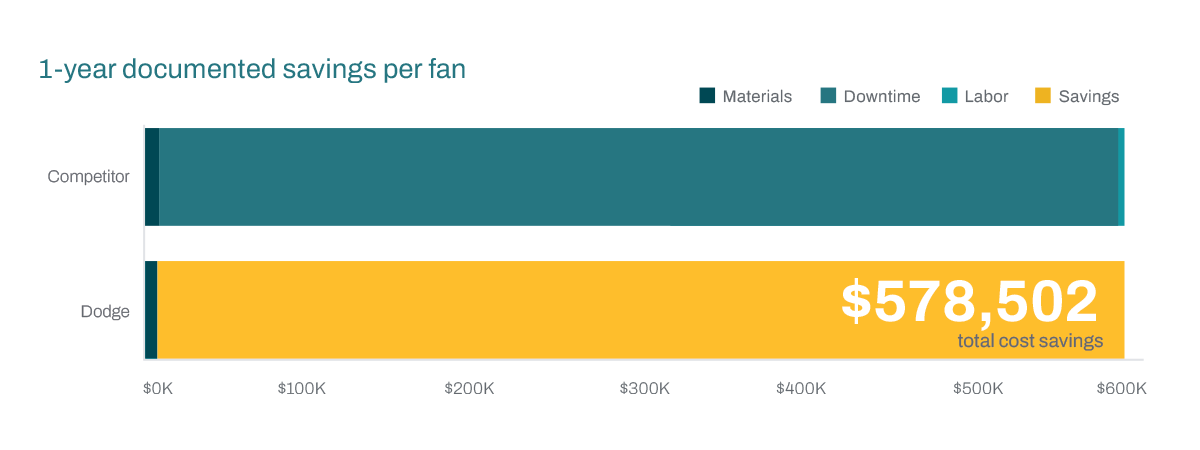

The existing 300-series mounted ball bearings on the air relief system’s 15 blower fans were overheating due to contamination from inferior sealing systems and required replacement three times each year per fan. Each bearing failure caused an unplanned shutdown that resulted in over $195,000 of material, labor, and downtime costs.

The Success

The installed Safety Mount ISAF bearings immediately demonstrated their superior performance, outlasting the existing 300-series mounted ball bearings and significantly improving system reliability—leading to an

average annual savings of

Proven solutions to withstand demanding applications

Improved reliability for reduced downtime and costs

Competitor bearings consistently failed, causing frequent shutdowns and excessive material, labor, and downtime costs.

The test

Plant management sought a more reliable solution for the critical production phase, as the existing bearings had a short lifespan due to contamination. During the test period, Dodge® Safety Mount ISAF bearings replaced the existing 300-series ball bearings and demonstrated superior performance and durability.

The results

The Safety Mount ISAF bearings significantly improved reliability in the air relief system, showing no signs of failure due to overheating. Plant management decided to implement Safety Mount ISAF bearings on all 15 blower fans to reduce maintenance costs, eliminate unplanned downtime, and maximize production output.

Safety Mount ISAF bearings are being installed on all air relief system fans in the manufacturing facility due to reduced maintenance and superior performance.

The why

The Safety Mount ISAF bearing features an innovative design and delivers superior performance in demanding, highly-contaminated applications. Its labyrinth seal option with corrosion-resistant flingers and steel clearance seals protects against contamination in high-speed and high-operating temperature applications—making it ideal for meat rendering and grain grinding to significantly improve equipment reliability.

Engineered to provide a direct path for fresh grease to its rolling elements, Safety Mount ISAF bearings optimize lubrication and efficiently purge old grease to prevent contamination buildup—reducing maintenance and maximizing reliability. Built for demanding applications, the Safety Mount ISAF bearing is the premier solution you need to keep production flowing smoothly.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.