Las Vegas airport bets on Dodge

Before September 11, 2001, passengers kept their shoes buckled, gate greetings and goodbyes were photo ops with family and friends, and the Transportation Security Administration did not exist. However, now, additional security screenings are daily routines at airports throughout the country. The federal government created the changes to help ensure the safety of airlines and passengers. Some of those changes included the installation of explosive detection equipment, which scans all checked baggage before it is loaded on an aircraft.

The Harry Reid International Airport, recently named after the late Nevada Senator Harry Reid and formally known as the McCarran International Airport in Las Vegas, is one of the busiest airports in the country. After September 11, the Department of Homeland Security awarded the airport more than $93 million to help with costs to install the high-tech explosive equipment and additional conveyors. With more than nine miles of conveyors, the airport’s planning department wanted maximum efficiency 24/7. Therefore, the department chose Dodge Industrial, Inc., an RBC Bearings company, to provide products that would keep conveyors up and running.

“Reliability is the key reason we chose Dodge products,” Patrick Morrissey, the senior facilities maintenance technician, said during the time of installation. Many airlines are turning aircraft in 15 minutes, and a breakdown in the checked-baggage line would mess up flights across the country. We just can’t afford to be down.”

The planning department also invested in the in-bound baggage handling with Dodge products. They chose the Dodge Quantis right angle helical bevel gearbox with twin tapered bushings as their gearing choice. The product offers greater torque density in a more compact design and the increased ration ranges provide a cost-effective lower speed solution. Morrissey said they specifically liked the advantages the twin tapered bushings offered with their positive, easy-on, easy-off mounting capability.

“You can buy a cheaper product, but you’ll waste time and effort replacing it sooner than you want to,” Morrissey said. “The Dodge product is quality and will last, and when we do have to replace it years down the road, it will come right off—it will be a quick change-out that will cost us less downtime.”

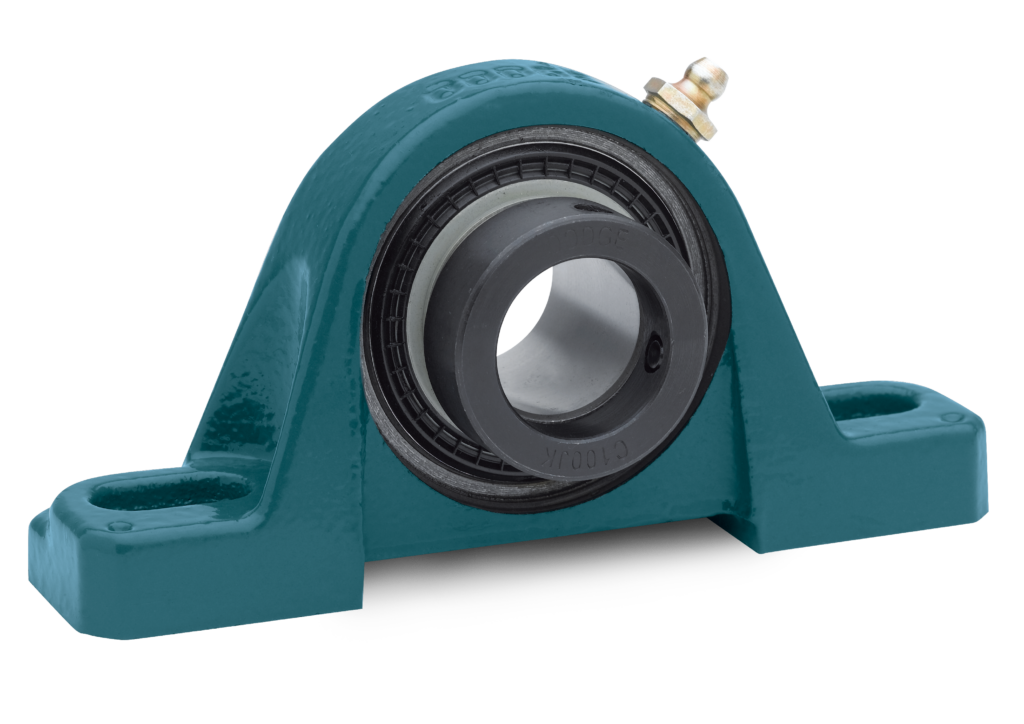

The airport team also chose Dodge eccentric collar ball bearings, a product specifically designed for airport baggage-handling applications. The bearings are manufactured for the speeds and loads of equipment and accept a snap-in style end-cover that won’t fall off from bumping or jarring. The bearings are also lubed for life. Morrissey said he also appreciates the ease of doing business with Dodge. “We wanted reliability and dependability and that’s why we chose Dodge,” he said.