SUCCESS STORY | GEARING

No More Wasted Time or Savings

Wastewater industry

Synopsis

- Application: Oxidation ditch disc aerator

- Problem: Excessive labor maintenance costs

- Solution: Motorized Torque-Arm (MTA) gear reducer

The problem

A wastewater treatment facility for a West Coast city faced a critical challenge that would redefine their operational landscape. Common to many wastewater facilities, an oxidation ditch plays a crucial role in effectively removing organic matter from influent water by rotating a shaft with discs to aerate a modified sludge.

Operating around the clock in a wet, corrosive environment, gear reducers are critical to the oxidation ditch disc aerator drive system to keep the treatment process flowing smoothly. Weekly gear reducer mechanical checks and belt inspections every 6 weeks by two qualified technicians consumed valuable resources—costing the facility over $64,000 in annual labor for required maintenance.

Further compounding maintenance challenges, the facility was grappling with a competitive belt-driven gear reducer with an obsolete design which made finding replacement parts nearly impossible and added unnecessary complexity to required maintenance.

The success

By switching to MTA, the plant was able to immediately reduce extensive maintenance requirements, improve system efficiency, and mitigate unnecessary downtime, resulting in an

average annual savings of

Proven reliability and performance

The direct-drive solution for maximum uptime

The existing belt-driven system with an obsolete gear reducer was innefficient and laborious to maintain, requiring frequent inspections by two technicians.

The test

Time-consuming belt maintenance for the inefficient belt-driven system led management to transition to MTA, a direct-drive solution, before the outdated competitive gear reducer failed which would have resulted in an expensive equivalent replacement.

The results

The initial MTA implementation improved reliability, enhanced system efficiency, and streamlined maintenance for the facility—saving at least 76 hours of labor over a year. With the immediate positive impact to facility operations, plant management decided to convert all three of their oxidation ditch applications over to using MTA.

MTA replaced the competitive gear reducer to convert the application to a direct-drive system, providing improved reliability and easier maintenance.

The why

MTA is a direct-drive gear reducer delivering industry-leading performance and reliability in a compact AGMA-rated design. Designed to be shaft-mounted, MTA can easily retrofit existing belt-driven applications with little to no modification. Featuring a patented twin-tapered bushing system, the gear reducer is easy to install and provides guaranteed gearbox removal with no loss in torque transmission. Its severe-duty backstop is the only one designed to operate with extreme-pressure (EP) lubricant to minimize the wear of internal components for long-lasting safety and durability. For operations with the most demanding applications, MTA is the premier direct-drive solution you need to streamline maintenance and maximize uptime.

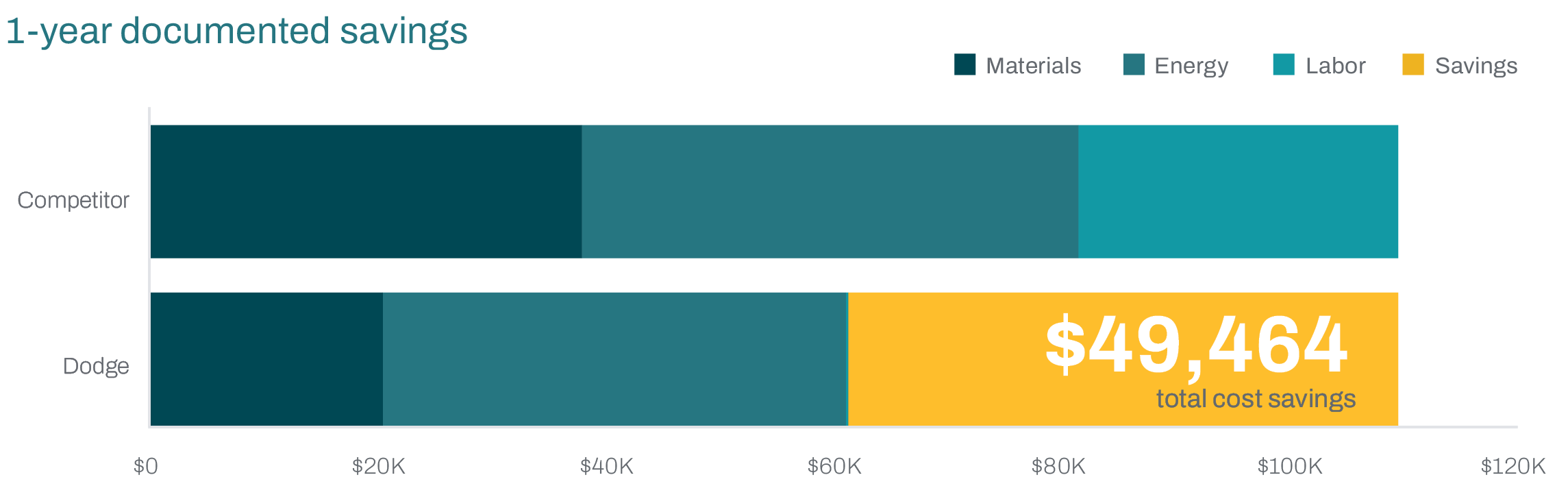

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.