OPTIFY™ Solutions Newsletter

Volume 3 | August 11, 2025

From downtime to uptime: how OPTIFY™ saves jaw crushers and budgets

Table of Contents

The primary crusher, often a Pitman-style jaw crusher, is one of the most critical components in an aggregate mining operation. Positioned between the haul trucks and the first conveyor, it performs the initial and most significant reduction in material size. Because there is typically only one primary crusher on site, it can become a single point of failure if issues arise or components fail, potentially halting production entirely. Any downtime at this stage quickly cascades through the operation, leading to low stock levels, idle labor, and reduced overall output.

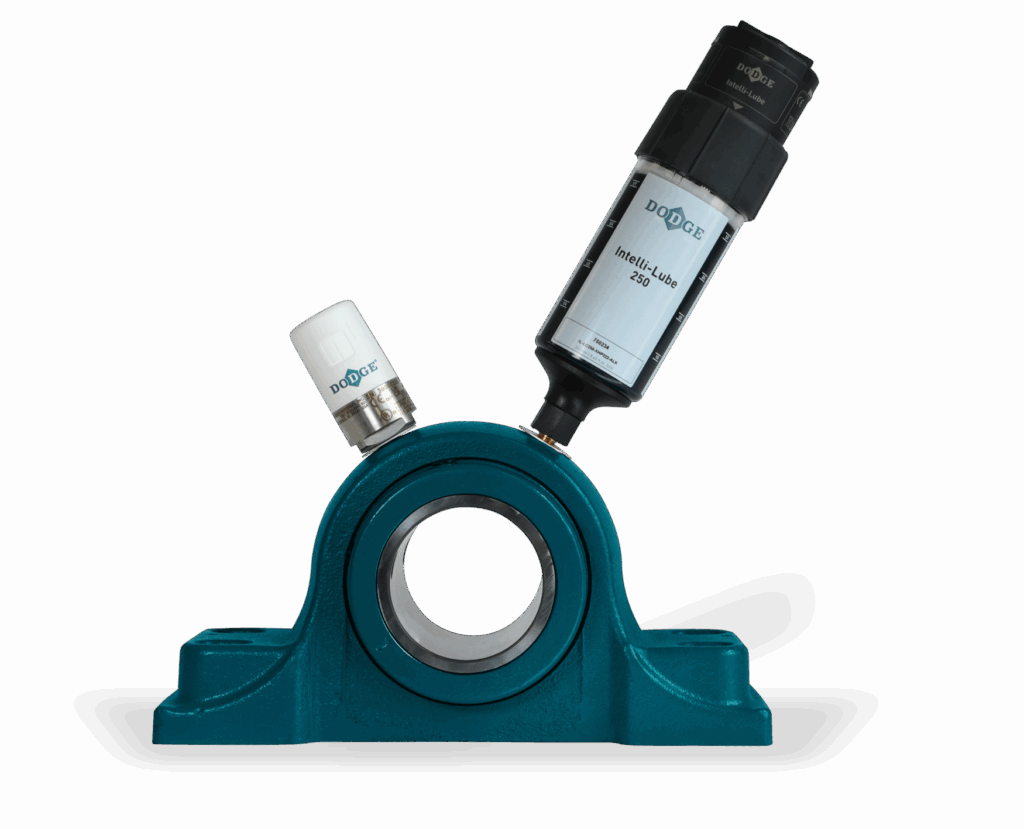

At the core of the jaw crusher is the Pitman arm, which moves back and forth on an eccentric shaft to drive the crushing action between the stationary and moving jaws. A well-designed arm delivers a long stroke for maximum crushing efficiency. The eccentric shaft is supported by four large mounted spherical roller bearings—two housed within the Pitman and two mounted in the frame’s heavy-duty steel bearing housings.

These bearings, particularly those supporting the Pitman shaft, are among the most common failure points in jaw crushers. Failures are often traced back to solid particle contamination, typically caused by inadequate lubrication.

What happens when overheating goes undetected

Before vibration monitoring was utilized , the jaw crusher’s drive bearing occasionally failed due to improper greasing and debris entering the bearing housing. In one case, the bearing temperature spiked to 800 degrees, warping the Pitman shaft and bending the rotor. Repairing a bent rotor is a major task, typically taking up to three days—assuming parts and equipment, such as a rental crane, are readily available. The minimum cost for this type of repair includes approximately $250,000 in parts and $50,000 in labor and equipment rental. Factoring in three days of lost production, roughly 30,000 tons of material, the total cost approaches $500,000—representing a significant hit to the plant’s budget.

Following the OPTIFY system deployment, two Pitman-style jaw crushers operated by a single customer at experienced similar bearing issues within the same week. One crusher was equipped with OPTIFY remote condition monitoring, while the other operated without it. At the monitored site, OPTIFY alerted the plant manager to an unusual temperature increase in the drive bearing. The manager immediately locked out the machine and removed the bearing housing cover. Though several rollers had failed, the damage was contained. The bearing was replaced, and the plant resumed operations the next day after only half a day of downtime.

In contrast, the unmonitored site experienced a more serious failure. The bearing failed without detection, causing damage to the housing and wearing down the rotor shaft. This necessitated a complete shaft replacement, resulting in eight days of downtime and approximately 32,000 tons of lost production. The delay was worsened by the unavailability of parts in the US, requiring the team to import bearing housings and cover plates from Paris at a high cost.

The bottom line is that a $40,000 problem can turn into a half-million-dollar problem unless you catch it early. Our platform fills that critical role of Pitman jaw crushers.

OPTIFY applied

Starlink gateway connection

Some remote locations can struggle with a cellular signal strong enough to maintain an OPTIFY Gateway connection. Because of this, we wanted to test the connection with Starlink satellite technology.

To do this, we ran a test in Canada to see how well gateways perform with satellite internet. Since satellite is widely used across Canada and many other countries, adding support for it gives you more flexibility when installing the platform in remote areas.

For the test, we used our standard gateway (part number 749972) and connected it to a Starlink network. Using Wi-Fi with WPA2-PSK security, the gateway connected to the cloud in under five minutes and has remained stable ever since. We also tested a wired connection, which delivered equally reliable performance with the same standard gateway.

Using satellite internet helps you maintain a stable and reliable gateway connection without needing to run additional Ethernet cables to a main network switch or deal with unreliable cellular service in remote areas.

This process lets you manage your own gateway network without relying on internal networks, which can be especially helpful if you’re more security-conscious. Since it uses the standard gateway instead of the e-SIM, the startup cost is significantly lower, but it does require you to maintain your own satellite internet subscription.

Conclusion:

- Connect from anywhere in the US or Canadian region, regardless of remoteness

- Maintain your own network connection for more visibility

- Uses a less expensive standard OPTIFY Gateway

- Bypass customer IT restrictions with a standalone satellite network

Basic vibration concepts and practical use cases for acceleration and velocity data

Vibration analysis is a foundational element of predictive maintenance in mechanical systems, enabling early detection of faults in rotating equipment such as motors, pumps, compressors, and turbines. Among the various types of vibration data, acceleration and velocity measurements each offer distinct insights into potential issues.

What high-acceleration vibrations indicate

Acceleration vibrations, measured in units like gravity (g), emphasize how quickly velocity is changing. This type of data is particularly sensitive to high-frequency phenomena, making it a powerful tool for identifying early-stage or small-scale issues.

- Bearing defects: High acceleration values often point to defects in rolling-element bearings, such as pitting, spalling, or inner/outer race damage. These faults generate very high-frequency impacts, easily detectable in acceleration data long before other metrics show signs.

- Gear mesh issues: Problems like worn gear teeth or backlash in gearboxes manifest as high-frequency vibrations. Acceleration data is useful here because it captures transient energy spikes that velocity or displacement data might miss.

- Cavitation and lubrication problems: In pumps or hydraulic systems, cavitation creates micro-implosions that lead to sharp, high-frequency vibration bursts. Similarly, poor lubrication in bearings or gears causes metal-to-metal contact that shows up strongly in the acceleration spectrum.

- Impacts or cracks: Acceleration sensors can detect short-duration impacts, such as those from loosened components tapping against housings or cracks propagating through material. These events may be too fast for velocity or displacement sensors to register clearly.

While acceleration data is less intuitive in terms of wear severity, it’s valuable for early detection.

What high-velocity vibrations indicate

Vibration velocity, usually measured in inches per second (in/s), reflects how fast a machine component is moving during vibration. High-velocity readings generally point to issues involving energy transfer due to looseness, imbalance, misalignment, or structural resonance.

- Imbalance: A common cause of high-velocity vibration, especially at running speed. When a rotating component has an uneven mass distribution, it creates centrifugal forces that increase vibration velocity. This is often a sign that the rotor needs balancing.

- Misalignment: Misaligned shafts or couplings can also show elevated velocity levels. These issues typically introduce harmonics and sidebands around the rotational frequency in the vibration spectrum, making them easier to diagnose.

- Looseness: Mechanical looseness—like a motor foot not being securely fastened—can cause an increase in vibration velocity. It often manifests as broad-spectrum vibration and affects multiple harmonics.

- Resonance: If a component is vibrating at or near its natural frequency due to an external force, velocity amplitudes can spike dramatically. Structural resonance issues can cause accelerated wear and even structural failure if not addressed promptly.

Velocity readings may point to issues that appear over time, since they are so closely related to the wear and tear in the overall system. Maintenance teams often use ISO vibration severity charts—based on velocity levels—as a baseline for assessing machine health.

By interpreting both high-acceleration and high-velocity vibrations together, maintenance teams can build a clearer picture of machine condition, from identifying early damage in bearings to pinpointing imbalance or looseness. Together, they form a robust diagnostic toolkit for predictive maintenance and operational efficiency. Our OPTIFY platform includes a range of vibration analysis tools that are accessible and easy to use, requiring minimal training.

What's new in the OPTIFY platform?

Smart alert management

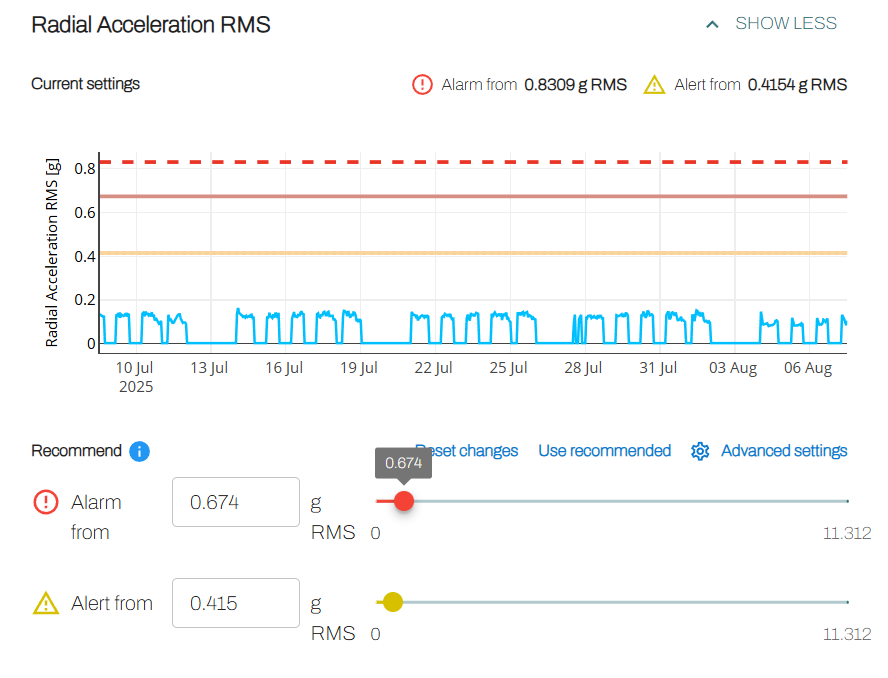

To enable this feature, head to your plant settings and select the option labeled “OPTIFY Automatically Sets Alerts/Alarms.” Once activated, you’ll start benefiting from intelligent threshold management—while still keeping full control of your monitoring system.

This new capability reflects our commitment to helping you manage your plant more efficiently without compromising safety. It works quietly in the background, learning from your operations and adapting to deliver optimal performance.

If you have any questions, reach out to your local Dodge® Sales Engineer or your OPTIFY support team—we’re here to help.

Critical steps:

- Smart learning period: The platform analyzes sensor data over five days to establish a baseline

- Comprehensive data collection: During this time, the system gathers at least 36 data samples to ensure accurate threshold settings

- Automated checks: Strategic evaluations are performed at 48, 72, 96, and 120 hours after commissioning to fine-tune alert and alarm levels

Three key benefits for plant administrators

- Effortless configuration

- Enable or disable automatic settings with a simple toggle

- Default to manual mode for maximum flexibility

- Exclusive access for plant administrators

- Complete transparency

- Detailed activity logs of all system modifications

- Clear timestamp records of threshold changes

- System-attributed changes for easy tracking

- Stay informed

- Instant email notifications when thresholds are updated

- Comprehensive update details, including:

- Sensor identification

- Previous and new threshold values

- Direct links to sensor settings

How to get started

The single most important success factor in any Industrial Internet of Things (IIoT) condition monitoring program is properly configured alerts and alarms. If thresholds are set too tightly, the system can trigger frequent false alarms, causing users to tune them out and lose trust in the platform. If they’re too loose, they can miss critical failures—leading to unplanned downtime, expensive repairs, and major hits to production. Getting the balance right is key to keeping operations running smoothly and avoiding costly surprises.

That’s why we’re excited to introduce a powerful new feature in the OPTIFY platform—automatic alert and alarm level configuration. This enhancement makes managing your plant’s monitoring system more efficient and reliable than ever.

After sensor commissioning, the platform now automatically calibrates alert and alarm thresholds. This ensures optimal monitoring performance without the need for manual adjustments, helping teams stay focused on what matters most—safe, uninterrupted production.

On and off scheduling for OPTIFY Intelli-Lube® drives

The OPTIFY platform is shaped by you. Thanks to your feedback, we’ve added lubrication scheduling to the platform. Now, you can easily toggle lubrication off for Intelli-Lube units during scheduled intervals.

With this new feature, gateway-monitored Intelli-Lube units can now schedule when lubrication is turned off. You can configure intervals from 7 days to 6 months, ideal for planned downtime and a great way to save on grease and reduce costs.