SUCCESS STORY | MOUNTED BALL BEARINGS

Packing Savings and Sausages

Food processing industry

Synopsis

- Application: Drag conveyor belts

- Problem: Bearing failures every 3 to 6 months due to water ingress

- Solution: FoodSafe™ mounted ball bearings

The problem

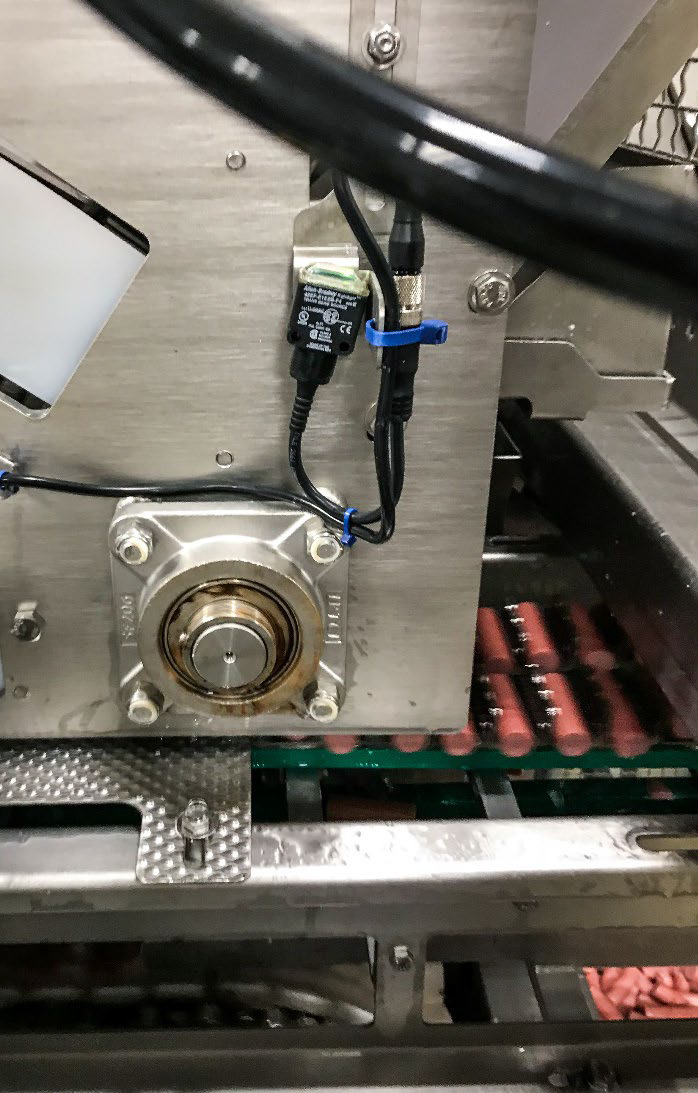

An industry leader and Ohio-based canned sausage producer continually experienced unplanned downtime due to mounted ball bearing failures. Machines throughout the facility are repeatedly flushed with water and undergo daily high-pressure washdowns. With stringent process requirements in place to prevent spoilage, mechanical breakdowns cause downtime that incurs significant expenses.

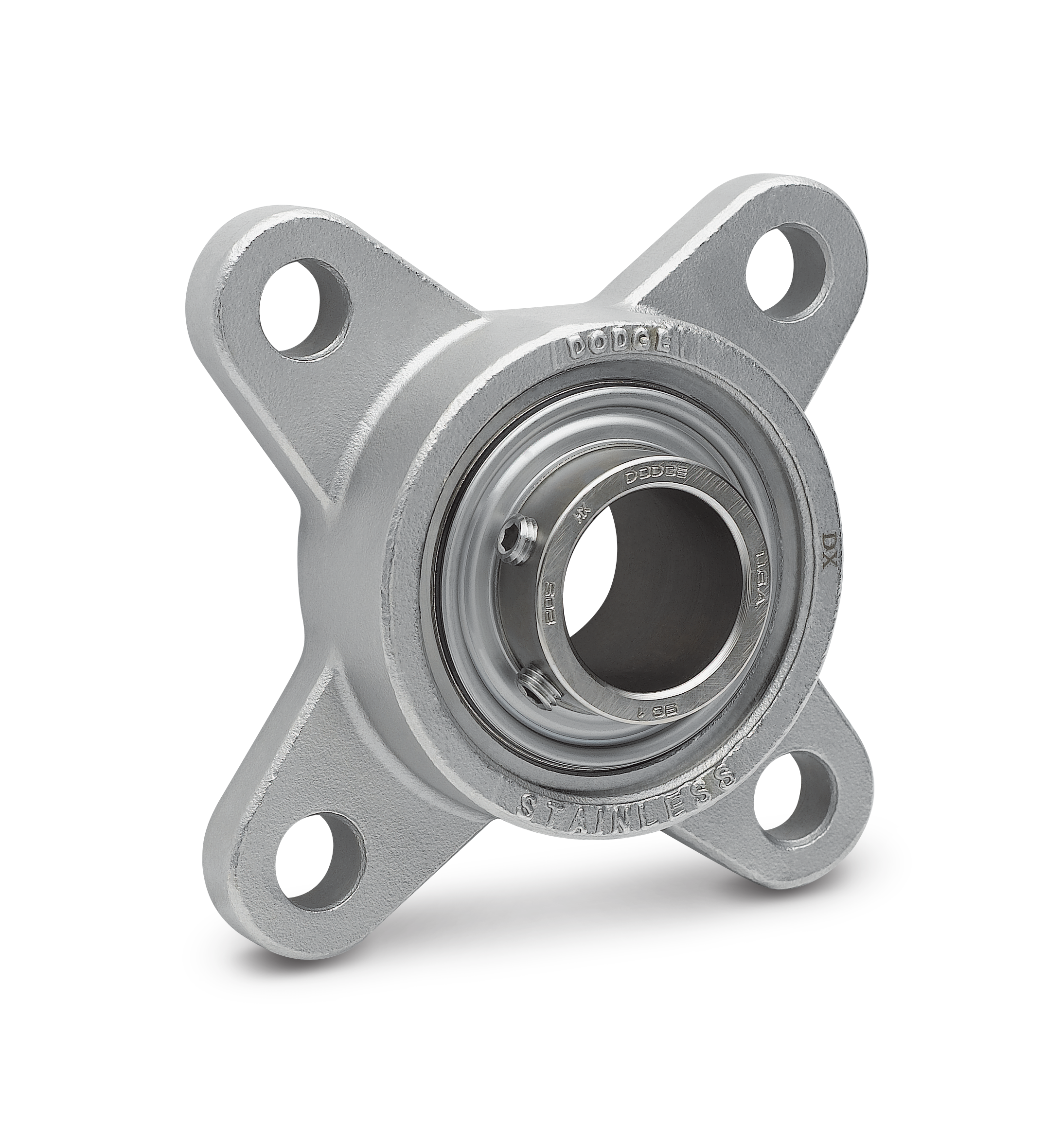

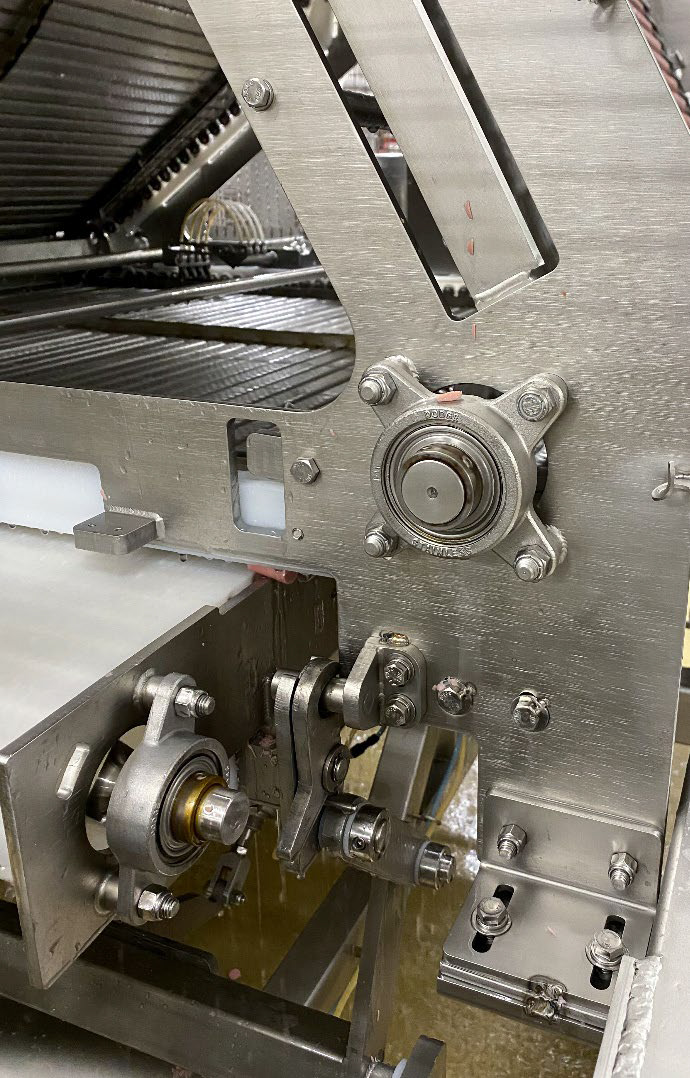

The machines are comprised of a winding set of drag conveyor-style belts, typically supported by a 1-1/4 inch, two- and four-bolt flange mounted ball bearings. Sliced sausages are carried through the machinery by slotted belt conveyors to be placed into cans before being sent to the next location for closing, heating, and finishing.

Regular washdowns performed on the machines caused water ingress, removing the grease in the cage and rolling element areas, which led to metal-on-metal contact that would worsen until failure—requiring bearing replacement every 3 to 6 months.

The success

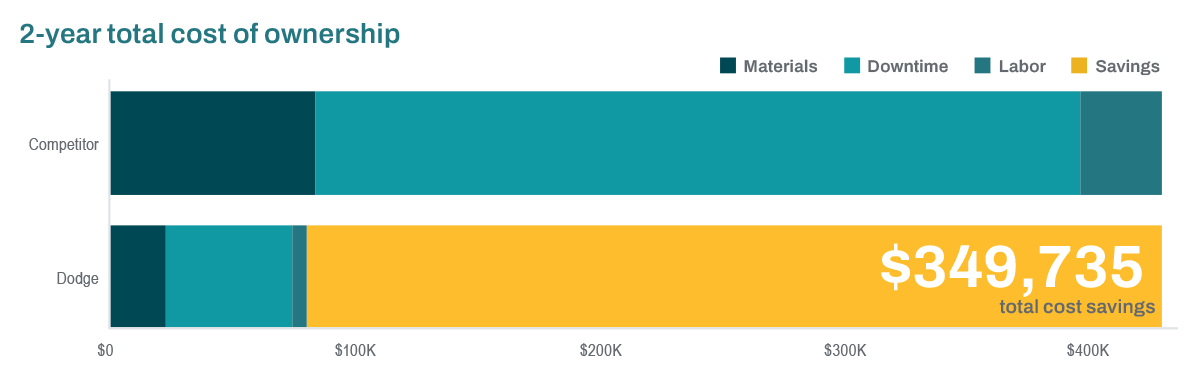

After a period of testing, plant management decided to replace every mounted ball bearing in their facility with FoodSafe mounted ball bearings, resulting in an

average annual savings of

Proven solutions to withstand washdowns

Reduced maintenance. Reduced cost.

The original bearings were replaced every 3 to 6 months due to failure from water ingress.

The test

In order to find a long-term solution, plant management tested Dodge® FoodSafe bearings against the competitor’s washdown bearings.

The results

After 1 year of testing, the competitor’s product showed obvious signs of lubrication leaking from the seals, while the FoodSafe bearings exhibited zero signs of leakage or failure—proving its superior performance.

FoodSafe bearings replaced every bearing throughout the facility due to their superior performance and reduced maintenance.

The why

Not only did performance over time set FoodSafe bearings apart from the competition, but their 1-year performance guarantee against failure due to water ingress and maintenance-free design elevated the plant managers’ confidence in the Dodge solution to the next level. Labor shortages and the lack of trained staff further fueled the plant managers’ decision to replace every single bearing in the sausage-canning facility with FoodSafe, totaling 108 bearings across three machines.

1-year documented savings

Ready to cut downtime, reduce maintenance, and drive real savings?

Fill out the form to connect with a Dodge expert to learn what implementing this solution could mean for your operation.