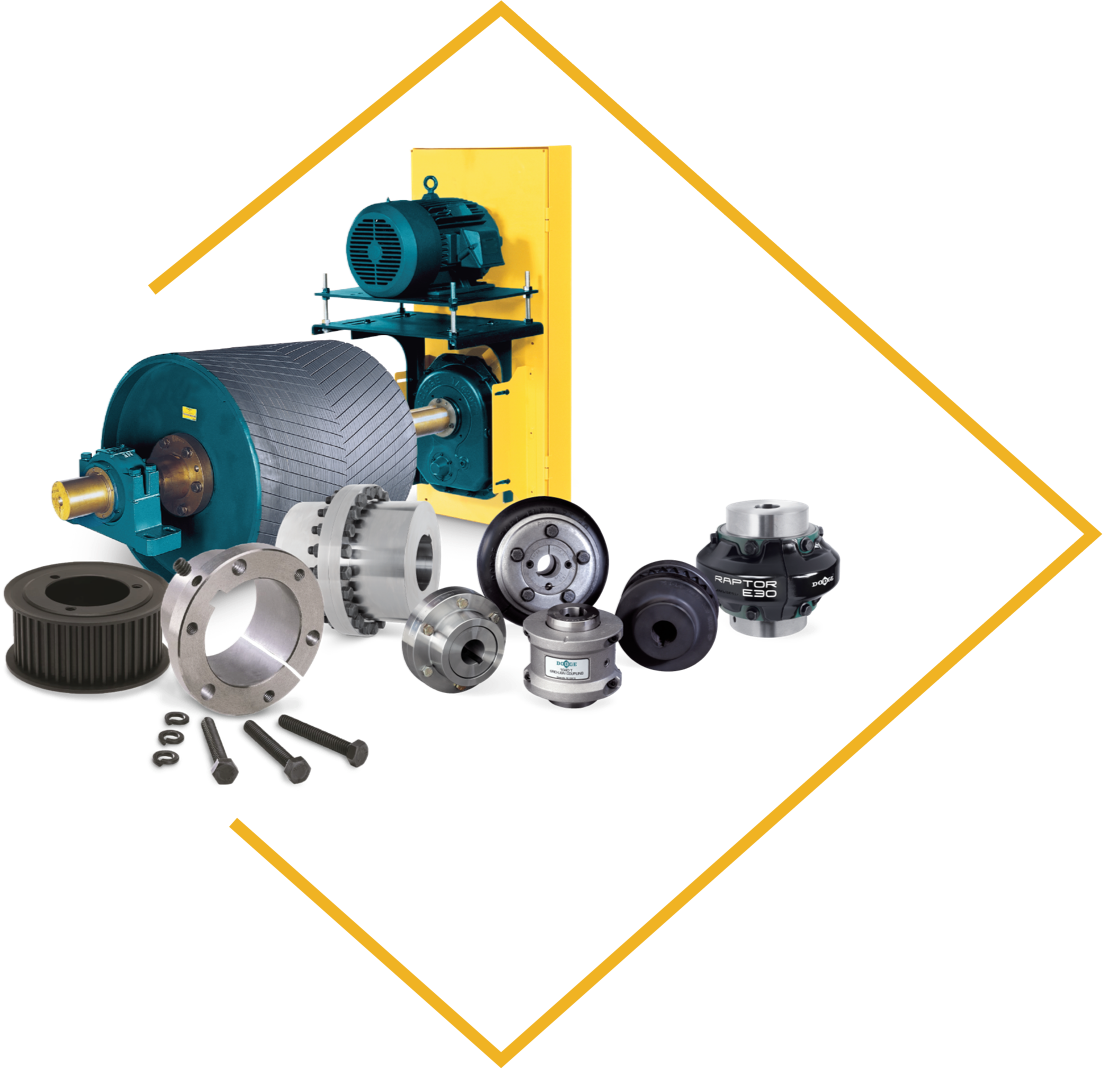

Mechanical Drives, Couplings, & Conveyor Components

A worldwide reputation for reliability and quality

Whether you are looking for mechanical drive components, couplings, or conveyor components, Dodge products maximize uptime in any application—allowing customers to meet their growing demands.

Our Offerings

Mechanical Drive Components

V-Belt Sheaves

Dodge v-drive sheaves are manufactured to ISO 9002 quality standards with precision machining that meets or exceeds joint RMA/MPTA industry standards for smooth operation and extended belt life. This design provides low economical costs per horsepower transmitted due to shock load and vibration isolation, creating clean, quiet operation.

Explore the catalog

V-Belts

V-belts allow for compact, lighter-weight drives and feature a high-strength tension member for rated power with minimum stretch. Their molded cog construction accommodates extended belt lengths. S-L classic, classic cog, polyband, and wedge v-belts are also available.

Explore the catalog

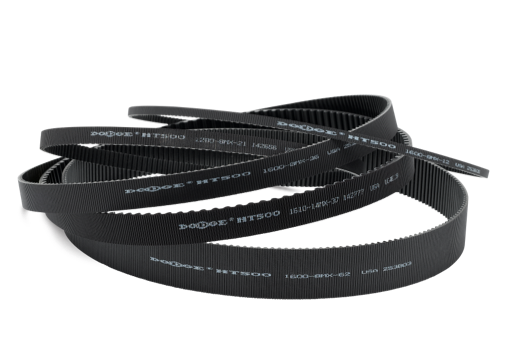

Synchronous Sprockets and Belts

Synchronous sprockets improve drives with a curvilinear timing belt. A reinforced belt wraps around and engages a motor-driven sprocket or pulley to transmit translational or rotational motion.

Explore the catalog

Roller Chain Sprockets

Roller chain sprockets reliably handle high shock loads and deliver large amounts of torque. For ease of installation and removal, Dodge offers roller chain sprockets featuring Taper-Lock bushings. Dodge also offers Torque-Tamer clutches, an overload protection device for roller-chain drives that protects the system’s driven equipment.

Explore the catalog

Motor Bases

Motor bases are made of steel, which offers a base of rugged design while being compact and smooth in appearance. Bases are designed to provide adequate travel and are fully adjustable by the use of a single adjusting screw and the elongated mounting holes in the base plate.

Explore the catalogCouplings

Elastomeric Couplings

Dodge elastomeric couplings are available in innovative designs such as the Raptor (split-tire), Para-Flex (tire), D-Flex (sleeve), and StarFlex (jaw). This large product offering delivers coupling solutions for virtually any application including pumps, compressors, and fans. Explore the catalog.

Learn more about:

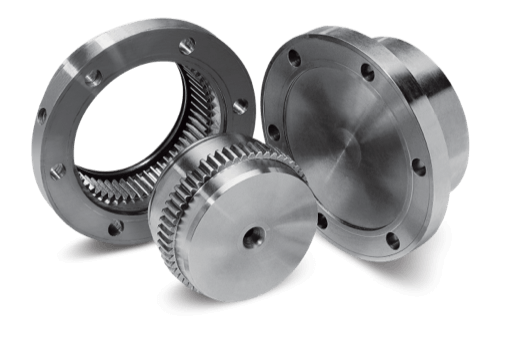

Metallic Couplings

Dodge metallic couplings are available in flexible designs such as grid, gear, and chain, as well as rigid designs such as Taper-Lock rigid, ribbed-rigid, and moment couplings. This broad offering delivers solutions across the torque spectrum, from pumping applications to packaging, with Dodge enclosed gearing for high-torque conveying applications.

Explore the catalog

Mechanical Soft Starts

Dodge fluid couplings are most commonly used on remote location conveyor drive applications in the mining, aggregate, cement, and power generation industries where controls and drives are difficult to power, program, and maintain.

Explore the catalogConveyor Components

Drum Pulleys

Dodge heavy-duty and mine-duty extra (MDX) drum pulleys deliver high performance and are available when you need them. Available from stock in many common sizes or custom-made, Dodge heavy-duty drum pulleys meet or exceed CEMA application standards for use with conveyor belts rated up to 750 PIW (Pounds per Inch of Belt Width) by 131 kN/m.

Explore the catalog

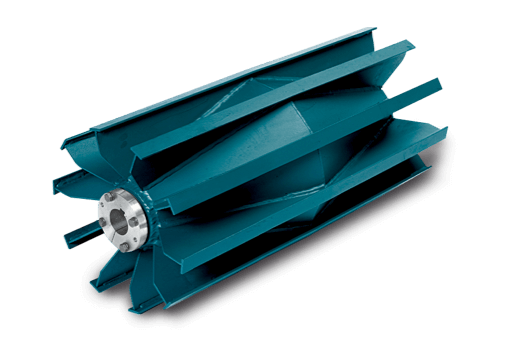

Wing Pulleys

Dodge wing pulleys deliver high performance and are available from stock in many common sizes. Dodge wing pulleys meet or exceed CEMA application standards for use with conveyor belts rated up to 450 PIW by 78 kN/m.

Explore the catalog

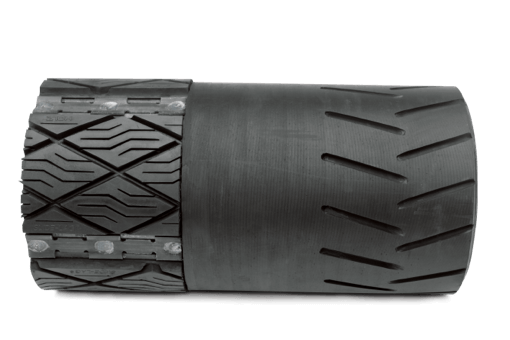

Lagging

Dodge conveyor pulleys can be provided with high-quality lagging, designed to ensure maximum belt and pulley life in tough applications. Dodge has the expertise to offer a full variety of lagging options, including vulcanized, cold-bond, and weld-on lagging.

Explore the catalog

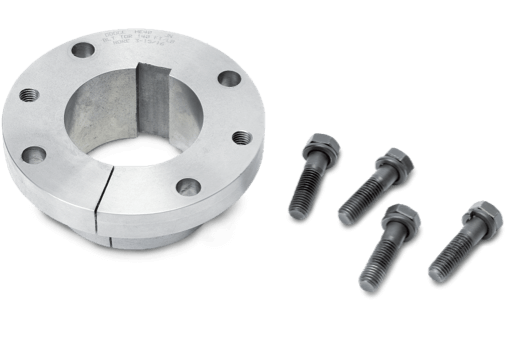

Bushings and Hubs

Dodge bushings have unique features and a high-endurance design that extend conveyor pulley life. Dodge also manufactures XT bushings, which are interchangeable with bushings found on competitive conveyor pulley products. Hubs are useful for welding into fan rotors, impellers, and agitators which require secure mounting to the shaft.

Explore the catalog