To gear up for even bigger jobs than before, the best-in-class direct-drive reducer lineup now features multiple enhancements for increased capabilities.

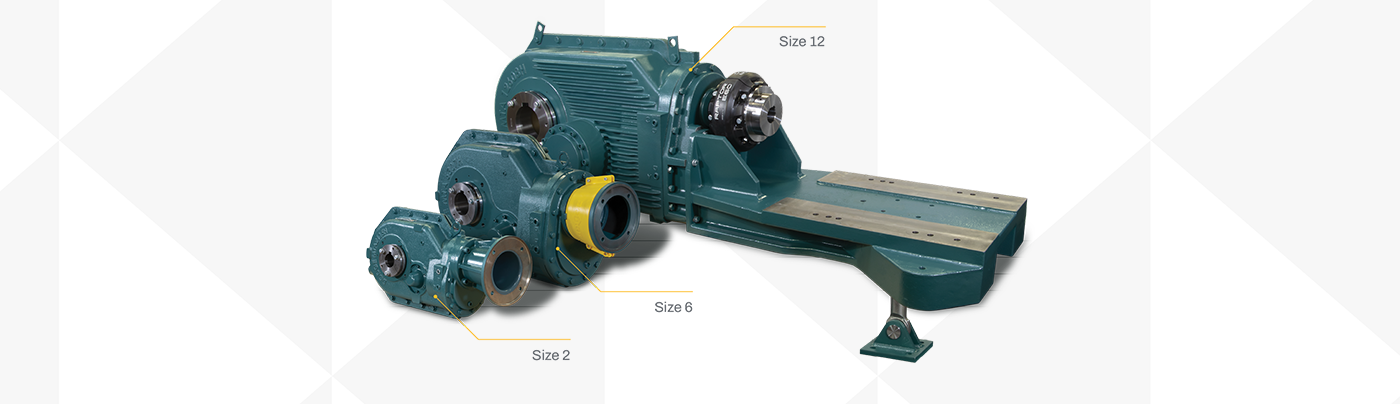

Dodge Industrial, Inc., a leading provider of innovative industrial solutions, is thrilled to announce three new advancements in its industry-leading Motorized Torque-Arm (MTA) lineup. Renowned for its reliability and safety, MTA is the only AGMA-rated, direct-drive reducer—and now, it’s bigger and better than ever with:

Larger-sized 9, 10, and 12 reducers to support up to 329,000 in-lbs of torque for ultimate application versatility, even for the most demanding applications

Assembly packages with reducers size 7 to 12 and patent-pending Atlas Adapter to support readily available large foot-mount motors 60 horsepower and above—reducing the need for critical spare motor inventory by allowing the use of standard foot-mount motors in sizes not commonly stocked in C-face styles

C-face safety input adapter to enable access to the coupling through its split cover to eliminate the need to remove the motor—enhancing on-site safety and streamlining maintenance

“At Dodge Industrial, our philosophy is to always go the extra mile. These MTA enhancements give customers a heavy-duty gear reducer designed to deliver industry-leading performance in the most extreme conditions and demanding applications,” says Jack Tavernier, Product Manager for MTA at Dodge. “Motorized Torque-Arm is the perfect example of that philosophy in action.”

MTA’s patented twin-tapered bushing system makes installation and removal easy, saving valuable time and effort, all while guaranteeing maximum torque transmission. It also offers the only backstop that operates with extreme pressure (EP) lubricant to minimize the wear of internal components for extended product life. Additionally, the patented premium-sealing systems minimize maintenance while maximizing uptime.

Discover how Motorized Torque-Arm is the premier solution for demanding applications by visiting https://info.dodgeindustrial.com/mta/.